- 25

- Oct

How Much is Automatic Block Machine Price?

Raytone block machine manufacturer is offering a wide range of full automatic block machine price from 10000 USD to 92000 USD; the automatic block machine price is based on FOB Qingdao port, China.

Automatic block making machine is used to making different size concrete hollow blocks, color interlocking bricks, color paving bricks, curbstones, etc

Raytone Automatic block machine is designed on automatic system, it can work 24 hours continuously, the automatic block machine price and automatic block machine models are list out in this article.

All the automatic block machine are hydraulic operated except the QT4-25 models; hydraulic operated automatic block machine can make both concrete blocks and paver bricks with color surface, while QT4-25 automatic block machine is mechanical, which cannot make color surface paver bricks, but can make paver bricks without color surface;

1.The models of automatic block machine with price:

Large Automatic Block Machine: QT12-15, QT10-15, QT8-15

Middle Automatic Block Machine QT6-15, QT5-15, QT4-15

Simple Automatic Block Machine QT4-18, QT4-25

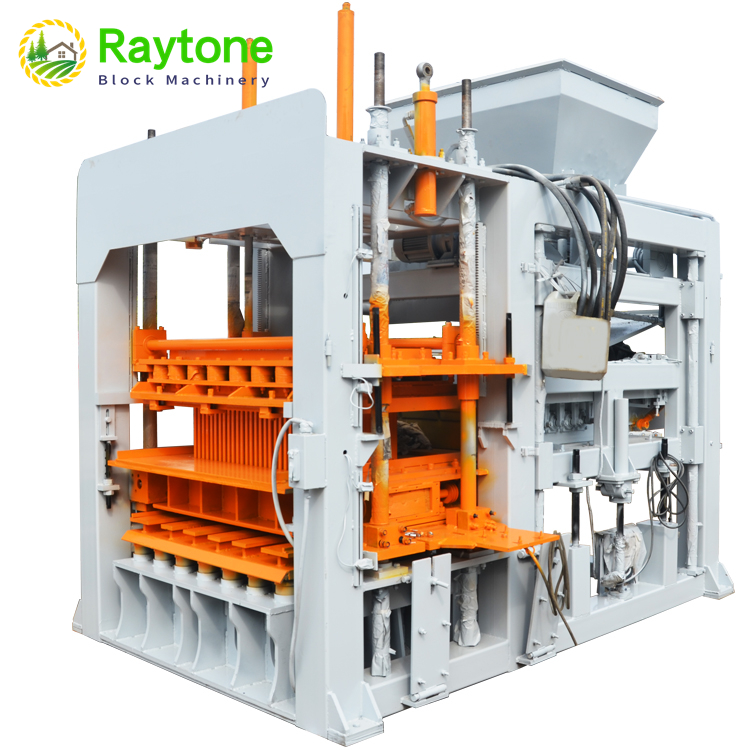

QT12-15 Automatic Hydraulic Block Making Machine |

|

|

| Descriptions: |

| QT12-15 is a static fully automatic brick and block making machine with hydraulic transmission system. It is matched with, Cement silo, 3 bin PLD1200 concrete batching machine, 750 liters concrete mixer, wet block stacking machine; also the auto brick pallet feeder and block cuber can be offered.

The robust and well constructed block making machine are hydraulic operation, two or four electric motors vibration, to insure the best compaction for producing high quality bricks and blocks.

|

| Specifications: |

| 1.Mould Changeable, Hollow block mould, Solid brick mould, Color Paver brick mould, Curbstone,etc |

| 2. Capacity per 8 hours: |

| a. 8 inch Block Capacity: 23040 pieces; |

| b. 240*115*50mm solid bricks: 124800 pieces; |

| 3.Brick pallet size: 1300*900*35mm |

| 4. Automatic Block Machine Price:51400-91200USD |

| 5. Factory Area: 2500-6500 m2; Workers Number:4-5; |

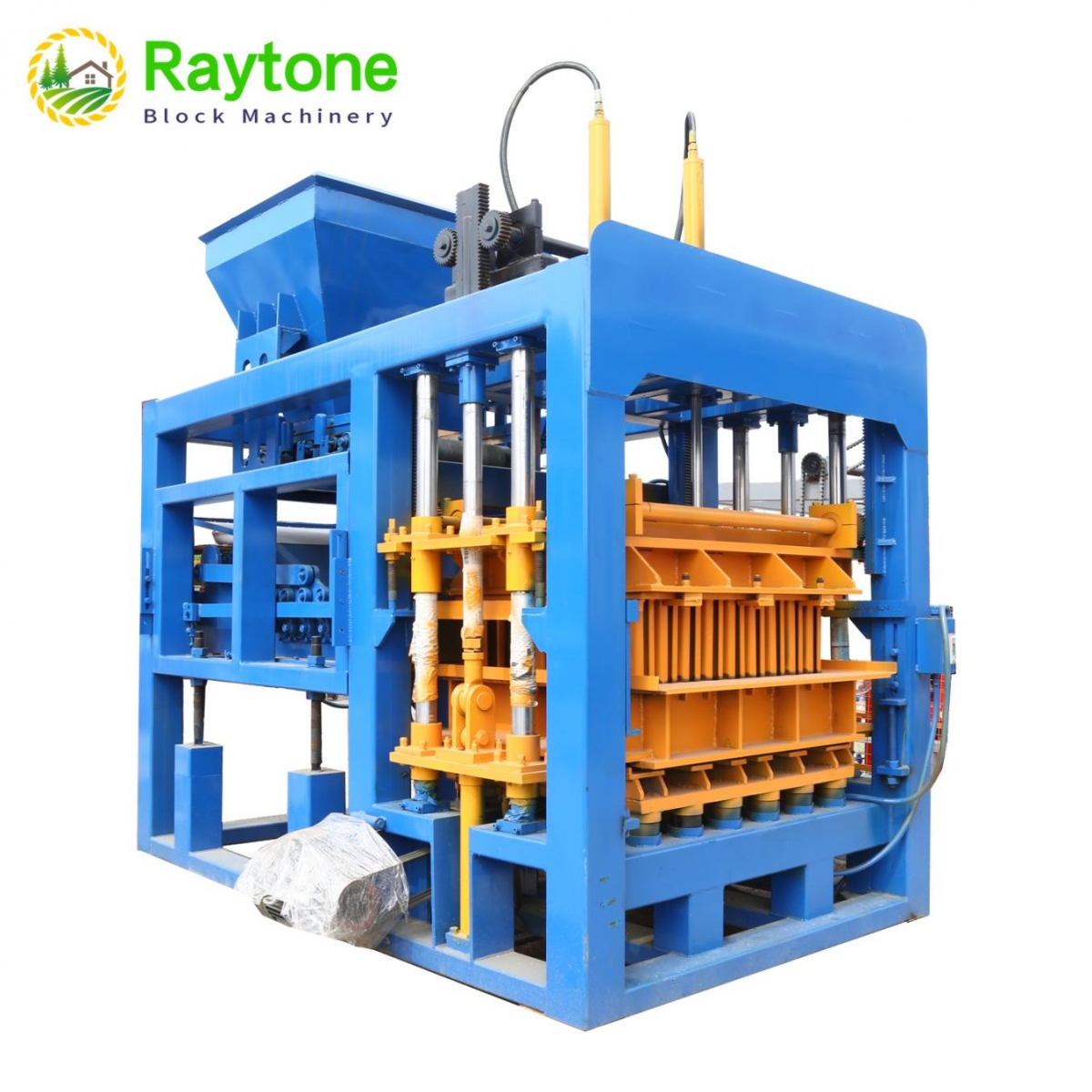

QT10-15 Automatic Hydraulic Brick Making Machine |

|

|

| Descriptions: |

| QT10-15 brick machine moulds are easily inter-changeable, allowing a wide production range of different block and bricks; The block machine can be optionally equipped with color feeder to make face mix bricks; It has a high speed of the translation of up and downs machine movements; The brick and block making machine is a reliable, durable and very easy to operate and maintain machine. |

| Specifications: |

| 1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours: |

| a. 8 inch Block Capacity: 19200 pieces; |

| b. 240*115*50mm solid bricks: 99840 pieces; |

| 3.Brick pallet size: 1100*900*35mm |

| 4. Automatic Block Machine Price:49400-82000USD |

| 5.Factory Area: 2500-6500 m2; Workers Number:4-5; |

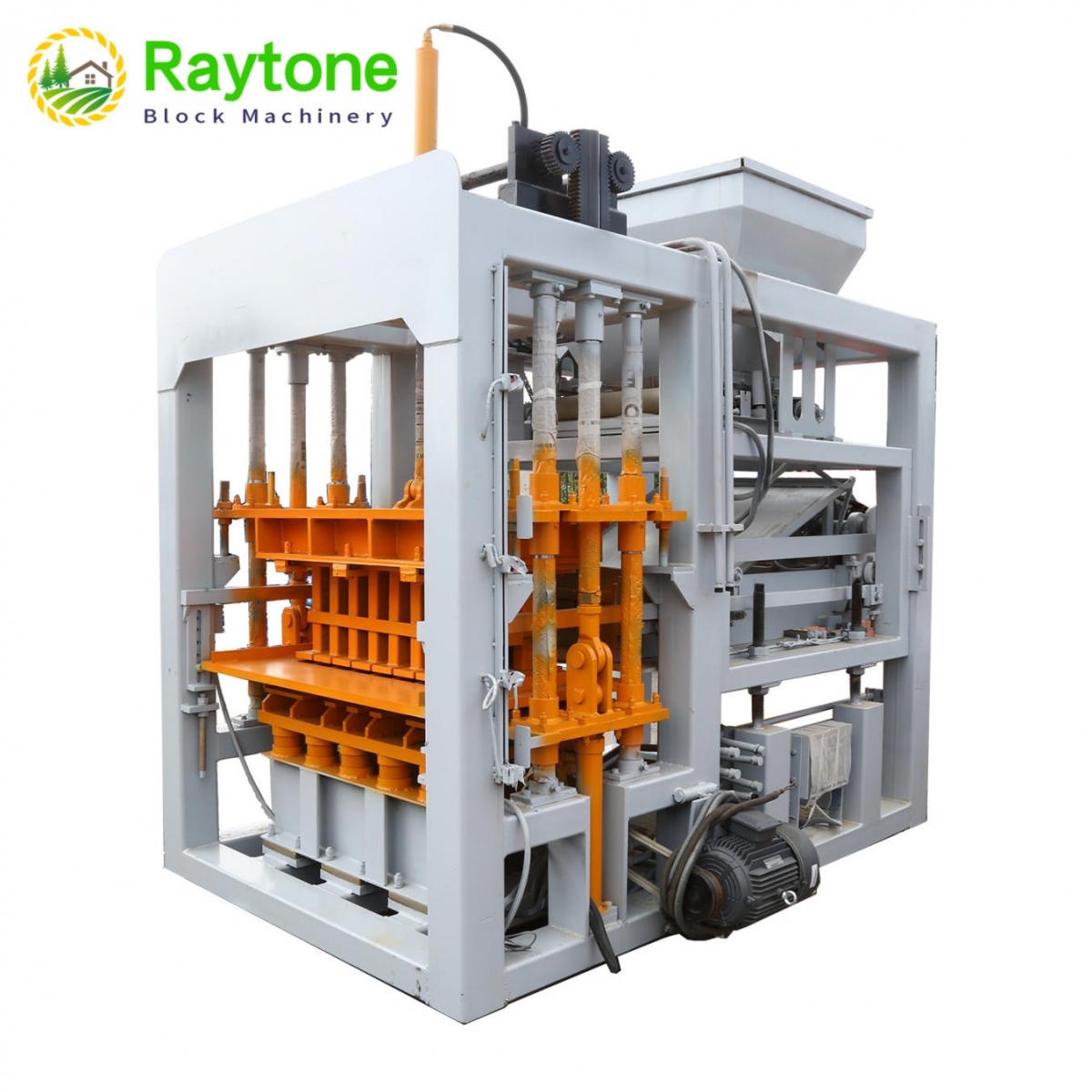

QT8-15 Automatic Hydraulic Concrete Block Making Machine |

|

|

| Descriptions: |

| QT8-15 Concrete block machine is also a big size machine, its PLC control panel has Siemens brand as optional, the internal electric parts are world famous brand like Germany Schneider breaker, Japan Omron Senors, China CHNT switches, China Vicruns Frequency converter, Taiwan Clyca brand electromagnetic valves etc. Also for electric motors with Siemens brand optional, The machine is coming standard with one maxi, hollow or stock block mould. Additional block moulds are at extra cost. QT8-15 is a high output block machine, with a great value for money. |

| Specifications: |

| 1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours: |

| a. 8 inch Block Capacity: 15360 pieces; |

| b. 240*115*50mm solid bricks: 80640 pieces; |

| 3.Brick pallet size: 960*850*30mm |

| 4. Automatic Block Machine Price:45400-70800USD |

| 5.Factory Area: 2500-6500 m2; Workers Number:4-5; |

QT6-15 Automatic Cement Brick Making Machine |

|

|

| Descriptions: |

| QT6-15 is a middle scale automatic concrete block machine model, it is equipped with 2 or 3 bin batching machine, 500 liters twin shaft concrete mixer, automatic wet block stacking machine; the automatic brick pallet feeder and brick face color feeder can be offered as optional. QT6-15 is also using User Friendly Touch Screen control on the PLC panel. QT6-15 block machine is well-constructed, have a stable vibration for high output brick that are ASBS compliant. |

| Specifications: |

| 1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours: |

| a. 8 inch Block Capacity: 11520 pieces; |

| b. 240*115*50mm solid bricks: 63360 pieces; |

| 3.Brick pallet size: 960*700*30mm |

| 4. Automatic Block Machine Price:32600-53400USD |

| 5.Factory Area: 1200-2500 m2; Workers Number:4-5; |

QT5-15 Automatic Curbstone Block Making Machine |

|

|

| Descriptions: |

| QT5-15 is a block machine dedicated for long curb block purpose, because its pallet is as long as 1150mm, can make the curbstone of maximum 1100mm length. High frequency electric motor vibration ensures optimal compaction for blocks, 15 seconds cycle time for block forming gives a maximum output for maximum profit. QT5-15 Block machine has the state-of-art vibration technology. |

| Specifications: |

| 1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours: |

| a. 8 inch Block Capacity: 9600 pieces; |

| b. 240*115*50mm solid bricks: 6144 pieces; |

| 3.Brick pallet size: 1150*550*30mm |

| 4. Automatic Block Machine Price:31600-51200USD |

| 5.Factory Area: 1200-2500 m2; Workers Number:4-5; |

QT4-15 Automatic Concrete Block Making Machine |

|

|

| Descriptions: |

| QT4-15 is a very popular automatic block machine model because of its affordable price. QT4-15 machine frame is made of high strength steel and skilled welding, to ensure the stable status for vibration motors vibrating to form blocks. QT4-15 block machine mouds frame is using high hardness 55# manganese steel, tampering head is using 16# manganese steel, after linear cutting, via carburizing and hot treatment, block mould hardness can reach 60 degree, lifespan can reach 10000 times; |

| Specifications: |

| 1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours: |

| a. 8 inch Block Capacity: 7680 pieces; |

| b. 240*115*50mm solid bricks: 57600 pieces; |

| 3.Brick pallet size: 960*550*25mm |

| 4. Automatic Block Machine Price:29100-46200USD |

| 5.Factory Area: 1200-2500 m2; Workers Number:4-5; |

QT4-18 Simple Automatic Block Making Machine |

|

|

| Descriptions: |

| QT4-18 is a simple hydraulic automatic concrete block making machine line, it is a good selling brick machine model, this machine has a good vibration performance and can equipped with face mix paver bricks, its PLC can be Siemens brand as optional, easy operation, it is one of our fist products; |

| Specifications: |

| 1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours: |

| a. 8 inch Block Capacity: 6400 pieces; |

| b. 240*115*50mm solid bricks: 41600 pieces; |

| 3.Brick pallet size: 880*550*25mm |

| 4. Automatic Block Machine Price:16100-29300USD |

| 5.Factory Area: 1200-1500 m2; Workers Number:3-4; |

QT4-25 Mechanical Automatic Concrete Block Making Machine |

|

|

| Descriptions: |

| QT4-25 is also automatic concrete block machine, but it is mechanical, not hydraulic, it is simpler than QT4-18 machine, but cannot make paver bricks with color because of short of hydraulic system. This is a good brick machine line for small investment, maximum profit for the investment. |

| Specifications: |

| 1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours: |

| a. 8 inch Block Capacity: 7680 pieces; |

| b. 240*115*50mm solid bricks: 57600 pieces; |

| 3.Brick pallet size: 880*550*25mm |

| 4. Automatic Block Machine Price:10000-16000USD |

| 5.Factory Area: 1200-1500 m2; Workers Number:3-4; |

2.The advantages of automatic concrete block machines:

(1)A high level of automation to saving labors

PLC electric control system is applied to the machine, and it fully controls all the procedures. The advanced fault diagnosis device will check and correct the errors automatically.

(2)Easy operation

It adopts the inverter control stack system, which ensures smooth and secure running. All the production processes, from feeding to stacking, are completed by the fully automatic production line control system.

(3)Low energy consumption

when the automatic brick machine comes into operation, the host machine is running all the time. While other engines run intermittently. The intermittent running ensures low energy consumption.

(4)Thermal Treatment

The block machine adopts a heavy-duty design and high-strength steel materials with advanced thermal treatment. The whole block machine and the molds are hard-wearing. The advanced technology applied to the machines prolongs the service life.

The Technical specification of Fully Automatic Brick Making Machine

Before buying or choosing any kind of brick making machine you need to consider the quality of the machine then the price. The price of the automatic brick making machine is offered as a complete plant “Turnkey Project”. Except for product drying and curing rooms, there is no extra equipment needed in the plant area.

3.Where to buy automatic brick making machine?

RAYTONE is an automatic block making machine manufacturer, with over 20 years of improvement and optimization. Our processing technology, services, and production capability make us the top automatic brick making machine supplier in China.

Raytone block machine manufacturer has sold the automatic block machine to many countries, like Philippines, Malaysia, India, Bangladesh, Nepal, Sri Lanka, South Africa, Malawi, Zambia, Zimbawe, Ghana, Ethiopia, Botswana, Guinea, etc

RAYTONE automatic block making machine, is also called RAYTONE fully automatic brick making machine or RAYTONE fully auto block making machine. RAYTONE automatic block making machine is one of the most advanced and customer-oriented automatic brick machine types for the middle and large production site. If you need the price of automatic block making machine, contact us now, we’ll send the price.

There are cement automatic block making machine, paver automatic brick making machine ,automatic paving block making machine, fly ash automatic block machine, hydraulic fully automatic block making machine, interlocking fully automatic block machine, hollow automatic block brick making machine, porous automatic block making machine, automatic block laying machine, automatic logo block making machine, etc.

4.Why choose RAYTONE block machine?

(1) For the steel raw materials , RAYTONE block machine is buying from China standard big steel factory to guarantee the raw materials quality first.

(2) For the welding, RAYTONE block machine manufacture workers are very experienced and skilled. They have many years work experience in brick machine making.

(3) For the PLC control panel, client can choose Germany Siemens brand, the hydraulic electromagnetic valves, RAYTONE block machine provides standard Taiwan CLYCA brand, but client can choose Japan YUKEN brand for optional, also for the sensor, RAYTONE block machine is using Japan Omron brand;

(4) RAYTONE block machine is using high manganese steel for block moulds, and strictly via Linear cutting , carbonized and heat treatment procedures, to make sure the block mould is with enough hardness for long life.

RAYTONE automatic block making machine supplies fully automatic block making plant and clay automatic block making plant for various block types, sizes, and dimensions. Each automatic blocking making machine mould can be customized according to your requirement. Drawings will be confirmed by you before production. RAYTONE automatic block making machine frame and mold adopt Q345 manganese steel (whole piece) with linear-cutting, hot treatment (for higher strength, leaving no dent after collision), water cooling .

(5) RAYTONE block machine design is advanced by reasonable raw material distributing system, Synchronous mould lift structure and vibration system;

5.What is the payment terms?

RAYTONE brick machine factory normally do 30% as deposit, after Raytone finish the production of concrete blocks, will take photo and video of the test, then send to the client for confirmation, then the client can pay balance by Telegraphic Transfer, after we receiving the payment, will book the shipment.

also the irrevocable Letter of Credit at sight is also acceptable from some countries;

6. How do you guarantee your block machine quality?

Firstly, In the process of equipment production, we check the quality of equipment production at any time, carry out ex-factory testing before shipment to ensure product quality. RAYTONE block machine manufacture has already more than 20 years experience in block machine making, we focus on every block machine quality to give our clients a good block machine with best advanced technology.

7. RAYTONE block machine manufacture company services

(1) Send the technicians to carry out the installation and debugging of equipment for the foreign users with compensation.and train local workers how to operated the block machine;

(2) If the client can send their workers to RAYTONE block machine factory, we can train the workers in our factory.

(3) Teach and guide the worker to do the trouble-shooting in the daily production.

If you need the price of automatic block making machine, please contact us now,