- 29

- Dec

QT4-35 Manual Brick Making Machine

QT4-35 Manual Brick Making Machine

1.QT4-35 Manual Brick Making Machine Generally Description

Based on simple design concept, this QT4-35 manual brick machine has simple machine structure but with raw materials hopper, so it can save labor cost and improve the productivity efficiency.

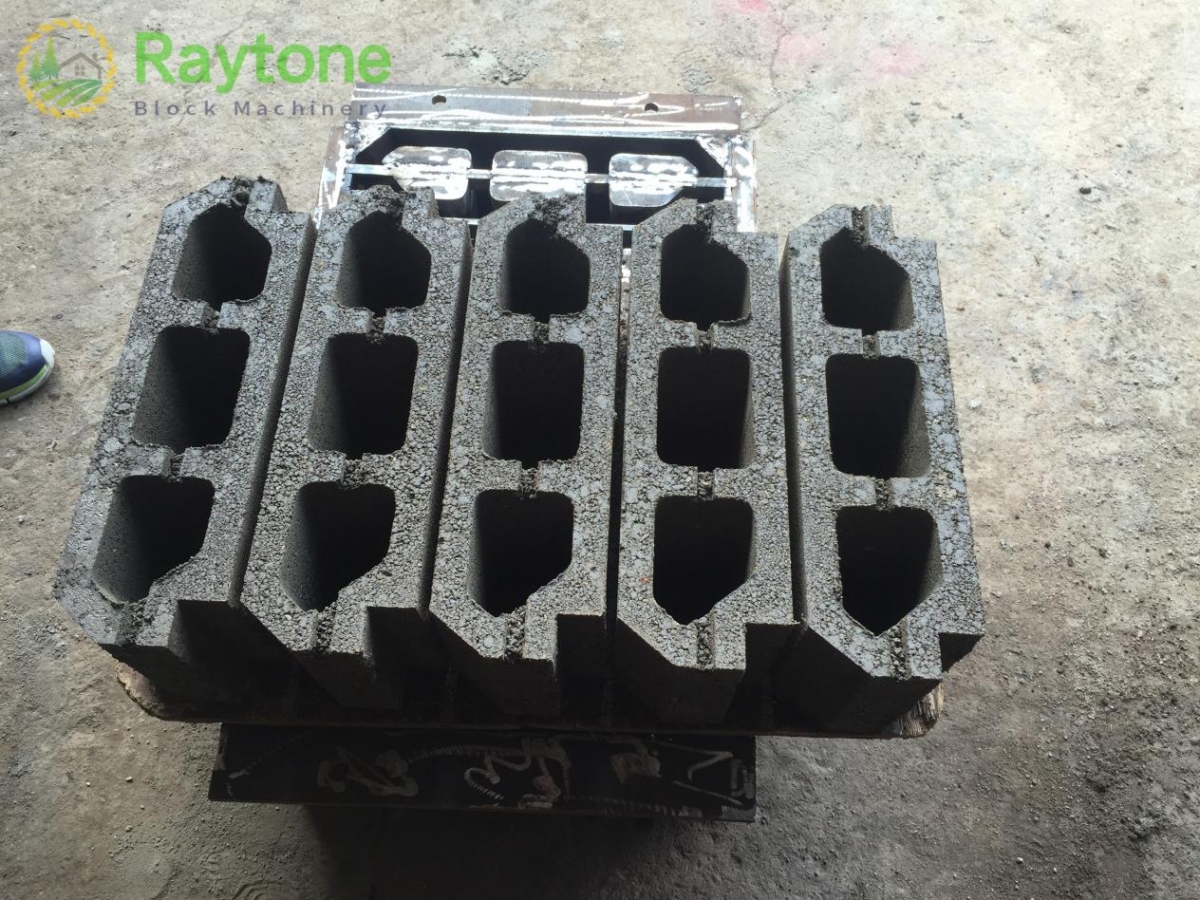

QT4-35 manual brick machine can make various size hollow block, paver bricks, curbstones etc from the raw materials of cement, sands, crushed stones or stone powder etc.

QT4-35 manual brick machine is also name QT40-1 manual block machine, its block moulds are all customized as per client requirements;

QT4-35 manual brick machine productivity is 2560-3290 pieces of 8 inch hollow blocks per day;

QT4-35 manual brick machine price is from 5000 USD to 15000 USD as per the extra block mould quantity;

2.QT4-35 Manual Brick Machine Production Requirements:

The following information is take 8 inch hollow block for example for the client reference, the production data may be a little different as per different block or brick producing

| land area | 200 Square Meters | Water Consumption | 1.8 T/day |

| Workshop area | 40 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 18.7KW*8 Hours=149.6 KWH; |

| Cement Consumption | 5.35 Tons per day | Sand consumption | 21.7 tons per day |

| Crushed stones consumption | 27 tons per day |

3. Each single machines detailed introduction for QT4-35 manual brick machine

(1) JQ350 concrete mixer for QT4-35 manual brick machine

function: to mix the raw material of sand, loosen stones, cement, etc

Item: JQ350 Mixer

Power: 7.5kw

Feeding capacity: 560L

Discharge capacity:350L

Overall dimension (mm):1500*1200*1200

There are two models of concrete pan mixer now, the first one is using the electric reducer model, the reducer is used since the pan mixer comes out, the reducer need to be maintained after several months use, and reducer can be replaced if it got broken;

The second model is using the truck rear axle gearbox model. This model doesn’t need to maintain, its life is very long, after the oil is filled in, it can be used all the time. But once the truck axle reducer got broken, it cannot be repaired, but its broken chance is very small.

Also for the concrete mixers, its inner side can add one piece of round steel plate to make it long life, and can also add the anti-wear bushes to protect the mixer.

(2) 6 Meters Belt Conveying Machine for QT4-35 manual brick making machine

Length: 6000mm

Belt width: 400mm

Motor power: 1.5KW

(3) Host manual brick machine

| (1) | Dimension of host machine | 1800*1500*2500mm | (6) | labour | 4 workers |

| (2) | Weight of the host machine | 1.5T | (7) | Voltage | customized |

| (3) | Moulding period | 35-45 | (8) | Toal required machine power | 23.15KW |

| (4) | pallet size | 850*550*20mm | (9) | Diesel Genset capacity | 30KVA |

| (5) | Vibration force | 50KN | (10) | workshop area | 200 m2 |

RAYTONE host QT4-35 manual brick machine also equip with the function of Electrical Push-pulling for the top mould by add an electric motor.

The QT4-35 manual block making machine is using vibration box instead of vibrator motors, this is one big difference with QT4-40 manual block machine.

for the electric panel, RAYTONE manual brick machine factory is using good quality buttons, good quality electrical parts.

(4) Manual Block Trolley for QT4-35 manual block machine

Function:The trolley is used to transport the blocks on pallet to curing area.Two trolleys are equipped for each machine;

RAYTONE block machine factory is using high quality wheels for the block trolley.

(5) Modified block machine line

The QT4-35 manual block machine can also be designed to be with a block conveying out platform, and equip with a stacking machine like the photo below:

4. Daily block productivity for QT4-35 manual brick making machine

| Theoretical production capacity | ||||||

| Size(LxWxH) (mm) | Photo | Forming Period (S) | Pcs/ Mould | Pcs/Hour | Pcs/ 8 hours | |

| (1) | hollow block 400*250*200 |

|

35-45 | 3 | 240-308 | 1920-2468 |

| (2) | hollow block 400*200*200 |

|

35-45 | 4 | 320-410 | 2560-3290 |

| (3) | hollow block 400*150*200 |

|

35-45 | 5 | 400-514 | 3200-4114 |

| (4) | hollow block 400*100*200 |

|

35-45 | 7 | 560-720 | 4480-5760 |

| (5) | Solid Brick 240*50*115 |

|

35-45 | 18 | 1440-1848 | 11520-14784 |

| (6) | Porous Brick 240*115*90 |

|

35-45 | 9 | 720-924 | 5760-7392 |

| (7) | Curbstone 500*200*300 |

|

35-45 | 1 | 80-102 | 640-816 |

| (8) | “I” shape paver brick without color 200*163*60 |

|

35-45 | 6 | 480-616 | 3840-4928 |

| (9) | “S” Shape Paver Brick without color 225*112.5*60 |

|

35-45 | 9 | 720-924 | 5760-7392 |

| (10) | Holland Brick without color 200*100*60 |

|

35-45 | 9 | 720-924 | 5760-7392 |

| (11) | Square Paver without color 250*250*60 |

|

35-45 | 3 | 240-308 | 1920-2468 |

5. Working Video Link for QT4-35 manual brick making machine

6.The produced blocks for QT4-35 manual brick making machine

7. Packing list for QT4-35 manual brick machine

| 1 | JQ350 Pan Mixer | 1 set | 5 | Manual trolleys | 2 sets |

| 2 | 6M belt conveying machine | 1 set | 6 | GMT brick pallet | 600 pieces |

| 3 | QT4-35 Host Brick Machine | 1 set | 7 | Spare parts | 1 set |

| 4 | Electrical PLC control Panel | 1 set | 8 | Free hollow block mould | 1 set |

8.GMT brick pallet for QT4-35 manual block machine

RAYTONE GMT brick pallet is containing of high content of high quality glass fiber, its life can reach 8 years.

The GMT brick pallet page link is as follow, please check for reference.

9. FAQ

(1) What is Packing method ?

For container loading, normally is it nude packing, it is safe in the container;

If by LCL, we an pack the block machine into wooden case or steel box, but need extra cost;

(2) How many workers are needed for the QT4-35 manual block machine?

The block machine need 4-5 workers, one operates the mixer and feeds material, one operates the host machine, and two workers transport the blocks. The office, curing area, stacking area are arranged according to your specific conditions.

(3)What’s motor and electric brand we choose for our machine?

RAYTONE block machine factory normally supply the China famous brand motors like HUAXING or SHANBO brand copper electric motors, not using any aluminium motors.

Some buyer can also choose Siemens brand motors, also need extra cost.

(4) What kind of steel my machine and molds use ?

RAYTONE block machine factory is using Q235B for block machine, Manganese steel for molds. The mould is More durable.

(5) Will you send engineer to install for user?

Yes, we have technician service team. They will supply service as per needs.

(6) Are there any spare parts together with the machine ?

Yes, we will send spare parts together with machine, the user could use more than two years.

(7)Do you supply free technical service during later production ?

Yes, we have online technical service in 24hours.

(8) What is the Warranty for the machine?

For the machine,we have 1 years warranty(except the wearing part ).

10. RAYTONE company service

During production service:

(1)Update the production schedule in time.

(2) Quality supervision during the whole production processing.

(3) Commissioning and debugging before delivery.

(4) Production acceptance. Customer can come to our factory for product inspection

(5) Test the block machine working video before delivery.

(6) Shipping on time. We guarantee the delivery time on time unless special cases.

After-sale Service

(7) Warranty period: 1year after acceptance. During this period, we offer you free spare parts if they are broken.

(8) Train the client’s staff how to install and use machine.

(9) Engineers available to service overseas.

(10) Skill support in the whole using life.

11. Another model of QT4-40 manual block machine for reference

Please contact RAYTONE block machine factory without hesitate if you have the plan to start block factory. RAYTONE will provide you the suitable brick plant solution.