- 01

- Mar

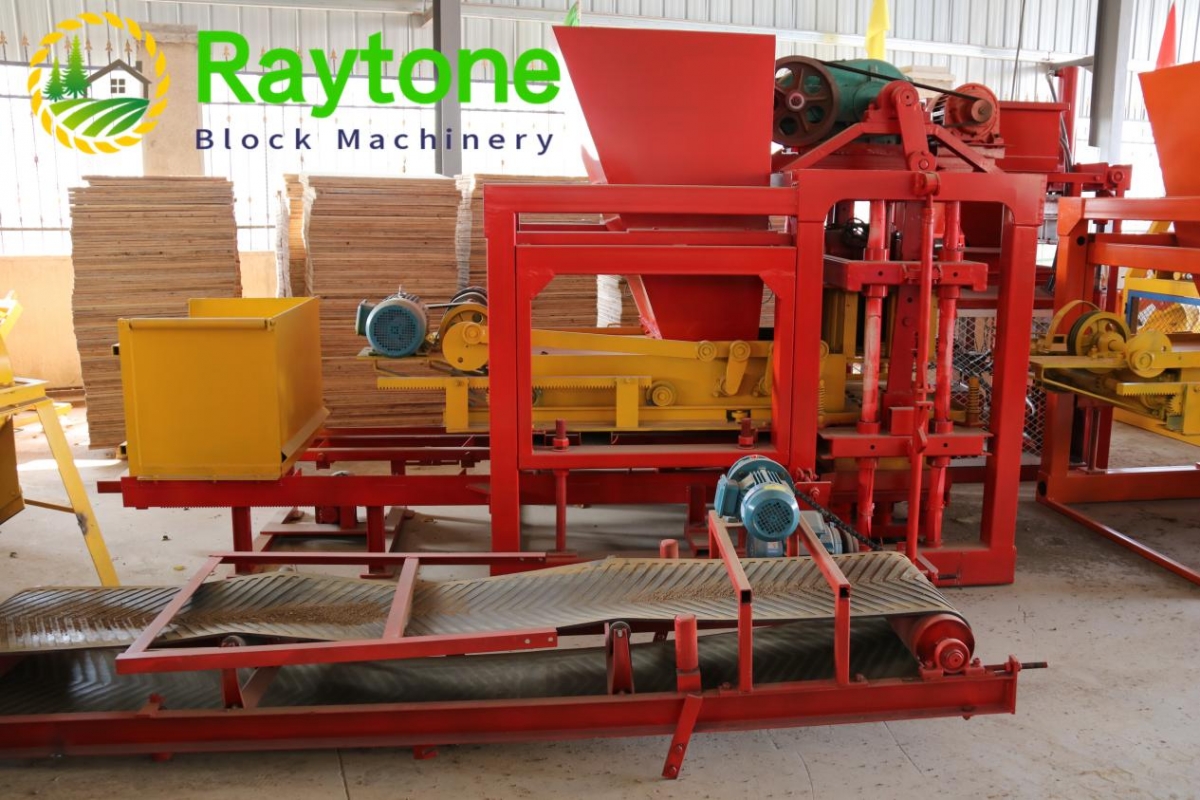

QT4-25 outomatiese sementblokmasjien

QT4-25 Outomatiese sementblokmasjien

1. QT4-25 Outomatiese sementblokmasjien Basiese beskrywing

QT4-25 outomatiese blokmasjien is a mechanical driven betonblok maak masjien, dit kan al die hol blokke, plaveiselstene, ineensluitende blokke, randstene ens maak, maar omdat dit nie toegerus is met pigmentvoermasjien nie, kan dit dus nie plaveiselstene met kleur maak nie;

QT4-25 outomatiese sementblok maak masjien can make 4 pieces of 8 inch hollow blocks per mould. Every mould cycle is 25 seconds;

QT4-25 outomatiese sementblokmasjien gebruik 880*550*22mm GMT baksteenpalet.

QT4-25 Automatic Cement block machine kan 4608 stukke van 8 duim hol blokke per dag maak;

QT4-25 Automatic Cement Block Machine price range is from 9600 USD to 25000 USD, the blokmasjien line cost is as per the extra blocks mould quantity.

2. QT4-25 Outomatiese sementblokmasjien line Basic Requirements for brick plant starting.

| grond gebied | 1000 SQM | Waterverbruik | 2.88 T/dag |

| Werkswinkel area | 60 SQM | Elektrisiteit Spanning & Frekwensie | 220V/380V/415V; 50HZ/60HZ |

| arbeid | 6 werkers | Kragverbruik | 34.8KW*8 ure= 278.4KWH; |

3. Paklys vir QT4-25 Outomatiese sementblokmasjien

| 1 | JQ500 Panmenger | 1 stel | 6 | Blokvervoermasjien | 1 stel |

| 2 | 6M band vervoerband | 1 stel | 7 | Blokke stapelmasjiene | 1 stel |

| 3 | Baksteenpalletvoerder | 1 stel | 8 | Handtrollies | 2 stel |

| 4 | QT4-25 Gasheer baksteenmasjien | 1 stel | 9 | GMT baksteen palet | 1000 stukke |

| 5 | PLC-beheerpaneel | 1 stel | 10 | Onderdele | 1 stel |

4. Detailed introduction of each single machine from QT4-25 outomatiese sementblokmasjien lyn

(1) JQ500 betonmenger

| Diameter: | 1.5 M |

| Input capacity: | 800L |

| Uitsetkapasiteit: | 500L |

| Produktiwiteit: | 20 cubic meters per hour |

| Power: | 11KW |

| gewig | 500KG |

(2) Bandvervoermasjien

| lengte | 6M |

| Power | 1.5KW |

| gewig | 300KG |

(3) QT4-25 Host brick Machine

| model | QT4-25 outomatiese blok masjien |

| Power: | 18.6KW |

| Vibration method: | Platformvibrasie |

| Pallet grootte | 880 * 550 * 22mm |

| Gewig: | 4000kg |

(4) Block Stacking machine

| Power: | 3.0KW |

| Gewig: | 500KG |

| aansoek: | Stack finished blocks one layer by one layer |

| grootte | 880 * 550 * 22mm |

| Gewig: | 12.8kg /piece |

| lewe | 8 jaar |

5. Daaglikse produktiwiteit van QT4-25 Outomatiese blokkeermasjien

| Teoretiese produksievermoë | ||||||

| Grootte (LxBxH) (mm) | foto | Vormingstydperk (S) | Stuks / Mould | St / Uur | Stk/ 8 uur | |

| (1) | hol blok 400*250*200 |

|

25 | 3 | 432 | 3456 |

| (2) | hol blok 400*200*200 |

|

25 | 4 | 576 | 4608 |

| (3) | hol blok 400*150*200 |

|

25 | 5 | 720 | 5760 |

| (4) | hol blok 400*100*200 |

|

25 | 7 | 1008 | 8064 |

| (5) | Soliede baksteen 240*53*115 |

|

25 | 26 | 3744 | 29952 |

| (6) | Poreuse baksteen 240*115*90 |

|

25 | 12 | 1728 | 13824 |

| (7) | Randsteen 500*200*300 |

|

25 | 2 | 288 | 2304 |

| (8) | “I” vorm plaveiselsteen sonder kleur 200*163*60 |

|

25 | 8 | 1152 | 9216 |

| (9) | “S” Shape Paver Brick sonder kleur 225*112.5*60 |

|

25 | 12 | 1728 | 13824 |

| (10) | Holland Baksteen sonder kleur 200*100*60 |

|

25 | 14 | 2016 | 16128 |

| (11) | Square Paver sonder kleur 250*250*60 |

|

25 | 3 | 432 | 3456 |

6. Werkende video’s van QT4-25 outomatiese sementblokmasjien

7. Photos of block and bricks made by QT4-25 outomatiese sementblokmasjien

8. Hoekom kies RAYTONE QT4-25 outomatiese sementblokmasjien?

① RAYTONE blokmasjien electric motors are all using China famous brand COPPER motor, the motors are with durable life; the vibration motor is high frequency, large amplitude, has strong excitation force, there is no loos of vibration. Stable and long life;

② Raytone blok masjien vervaardiger is using Carbon Dioxide Arc Welding, it ensures the machine welding points to be strong, stable, and smooth surface;

③ Blokvorm is via numeriese beheermasjien lineêre sny, baie akkurate grootte; ook deur hoë temperatuur hittebehandeling om die vorm meer hardheid te maak, teen wrywing om langer lewe te kry;

9. Gereelde vrae oor QT4-25 automatic Cement Block Machine

① What is the diesel generator capacity for this QT4-25 automatic cement block machine line ?

It needs 50 KVA diesel generator;

② How many workers are needed for this automatic QT4-25 blokmasjien lyn?

Normally 6 workers are needed: 1 worker feeds raw materials into the concrete mixer. 1 worker feed brick pallets and operate the host brick machine; 2 workers carry the finished blocks to curing area; 2 workers watering the blocks and stack them after dry;

③ Wat is die hoof elektriese kabelgrootte vanaf die elektrisiteitstransformator:

Need to use copper 3*25+1*16mm electric cable for 380V 3 phase;

Of 3*35+1*16mm elektriese koperkabel vir 220V 3-fase;

④ What is the basic raw materials proportion for concrete blocks?

Raw material proportion for your reference:

a. Beton: 10% sement, 30% sand, 60% klein klippe

b. 10% sement, 90% klippoeier

c. 10% sement, 30% vliegas, 60% klippoeier

10. Raytone company service

RAYTONE blok masjien vervaardiger has a dedicated service team, both pre-sales service and after-sales service;

① Vir voorverkoopdiens,

we can provide professional suggestions like raw material batching, machine model selection, factory layout, factory profit analysis;

RAYTONE blok masjien vervaardiger can recommend the suitable block machine model as per the buyer’ budget, daily capacity demand, etc

Ons het 24 uur aanlyn diens

Ons kan die blokmasjienfabrieksbesoek reël en uitnodigingsbrief aan die koper stuur;

Stel die besonderhede van die blokmasjien bekend

② Sales service

Kommunikeer betyds met die koper vir blokmasjienproduksieskedule;

Gehaltebeheer en -toesig;

Block machine testing before delivery.

Aflewering betyds

③ Na-verkope diens

Die ingenieur sal die koper lei om die installering van ‘n betonblokmasjien te doen, te bedryf en om probleme op te los;

Vaardigheidsondersteuning vir die masjien die hele lewe

Recall the clients regularly to check if there is any technical need. Keep a good communication with the client;

WELKOM OM TE KUIER RAYTONE BLOCK MACHINE MANUFACTURER VIR VERDERE SAMEWERKING