- 01

- Mar

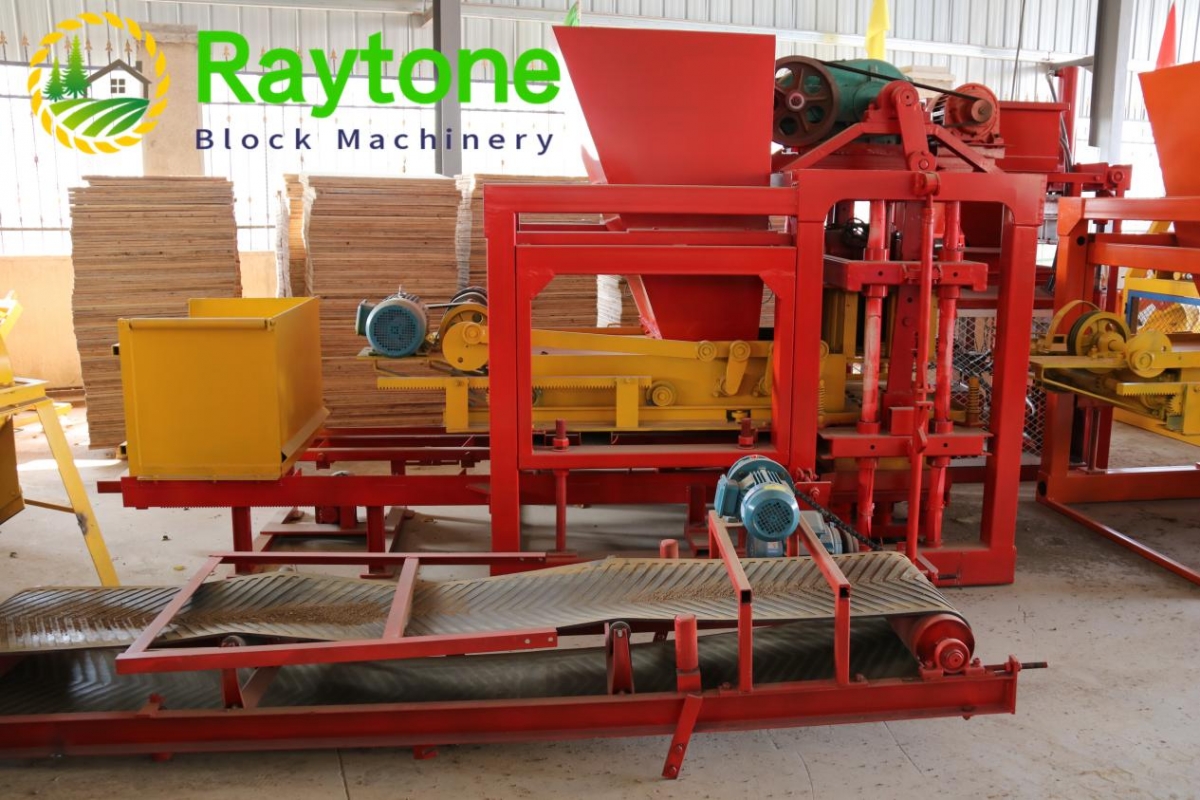

QT4-25全自動水泥砌塊機

QT4-25 自動水泥砌塊機

1. QT4-25 自動水泥砌塊機 基本說明

QT4-25 自動砌塊機 is a mechanical driven 混凝土砌塊機, it can makes all the hollow blocks, paver bricks, interlocking blocks, curbstones etc, but because it is not equipped with pigments feeding machine, so it can not make paver bricks with color;

QT4-25 automatic cement block making machine can make 4 pieces of 8 inch hollow blocks per mould. Every mould cycle is 25 seconds;

QT4-25 automatic cement block machine is using 880*550*22mm GMT brick pallet.

QT4-25 Automatic Cement block machine can make 4608 piece of 8 inch hollow blocks per day;

QT4-25 Automatic Cement Block Machine price range is from 9600 USD to 25000 USD, the 砌塊機 line cost is as per the extra blocks mould quantity.

2. QT4-25 Automatic cement Block Machine line Basic Requirements for brick plant starting.

| 土地面積 | 1000 SQM | 耗水量 | 2.88噸/天 |

| 車間面積 | 60 SQM | 電壓及頻率 | 220V/380V/415V; 50HZ/60HZ |

| 勞動 | 6工人 | 能量消耗 | 34.8KW*8小時=278.4KWH; |

3. QT4-25 裝箱單 自動水泥砌塊機

| 1 | JQ500盤式攪拌機 | 1集 | 6 | 砌塊輸送機 | 1集 |

| 2 | 6M皮帶輸送機 | 1集 | 7 | 砌塊堆垛機 | 1集 |

| 3 | 磚托盤給料機 | 1集 | 8 | 手推車 | 2集 |

| 4 | QT4-25主機磚機 | 1集 | 9 | GMT 磚托盤 | 1000件 |

| 5 | PLC控制面板 | 1集 | 10 | 備件 | 1集 |

4. Detailed introduction of each single machine from QT4-25 automatic cement block machine 線

(1) JQ500混凝土攪拌機

| 直徑: | 1.5中號 |

| Input capacity: | 800L |

| 輸出能力: | 500L |

| 生產率: | 20 cubic meters per hour |

| 電源: | 11KW |

| 重量 | 500KG |

(2) Belt Conveyor Machine

| 長度 | 6M |

| 充電 | 1.5KW |

| 重量 | 300KG |

(3) QT4-25 Host brick Machine

| 模特兒 | QT4-25全自動砌塊機 |

| 電源: | 18.6KW |

| Vibration method: | 平台振動 |

| 托盤尺寸 | 880 * 550 * 22mm |

| 重量: | 4000kg |

(4) Block Stacking machine

| 電源: | 3.0KW |

| 重量: | 500KG |

| 應用: | Stack finished blocks one layer by one layer |

(5) GMT 磚托盤

| 尺寸 | 880 * 550 * 22mm |

| 重量: | 12.8kg /piece |

| 生活 | 8年 |

5. QT4-25的日產量 自動砌塊機

| 理論生產能力 | ||||||

| 尺寸(LxWxH) (mm) | 上載照片 | 成型期(S) | 件/模具 | 個/小時 | 個/8小時 | |

| (1) | 空心砌塊400*250*200 |

|

25 | 3 | 432 | 3456 |

| (2) | 空心砌塊400*200*200 |

|

25 | 4 | 576 | 4608 |

| (3) | 空心砌塊400*150*200 |

|

25 | 5 | 720 | 5760 |

| (4) | 空心砌塊400*100*200 |

|

25 | 7 | 1008 | 8064 |

| (5) | 實心磚240*53*115 |

|

25 | 26 | 3744 | 29952 |

| (6) | 多孔磚240*115*90 |

|

25 | 12 | 1728 | 13824 |

| (7) | 路緣石500*200*300 |

|

25 | 2 | 288 | 2304 |

| (8) | “I”字形無色攤舖磚200*163*60 |

|

25 | 8 | 1152 | 9216 |

| (9) | “S”形無色鋪路磚225*112.5*60 |

|

25 | 12 | 1728 | 13824 |

| (10) | 荷蘭磚無色200*100*60 |

|

25 | 14 | 2016 | 16128 |

| (11) | 無色方形攤舖機250*250*60 |

|

25 | 3 | 432 | 3456 |

6. Working Videos of QT4-25 automatic cement block machine

7. Photos of block and bricks made by QT4-25 automatic cement block machine

8. Why choose RAYTONE QT4-25 automatic Cement block machine?

① RAYTONE 砌塊機 electric motors are all using China famous brand COPPER motor, the motors are with durable life; the vibration motor is high frequency, large amplitude, has strong excitation force, there is no loos of vibration. Stable and long life;

② Raytone block machine manufacturer is using Carbon Dioxide Arc Welding, it ensures the machine welding points to be strong, stable, and smooth surface;

③ Block mould are via numerical control machine linear cutting, very accurate size; also via high temperature heat-treatment to make the mould more hardness, anti-friction to gain longer life;

9. FAQ about QT4-25 automatic Cement Block Machine

① What is the diesel generator capacity for this QT4-25 automatic cement block machine line ?

It needs 50 KVA diesel generator;

② How many workers are needed for this automatic QT4-25 砌塊機 線?

Normally 6 workers are needed: 1 worker feeds raw materials into the concrete mixer. 1 worker feed brick pallets and operate the host brick machine; 2 workers carry the finished blocks to curing area; 2 workers watering the blocks and stack them after dry;

③ What is the main electric cable size from the electricity transformer:

Need to use copper 3*25+1*16mm electric cable for 380V 3 phase;

Or 3*35+1*16mm electric copper cable for 220V 3 phase;

④ What is the basic raw materials proportion for concrete blocks?

Raw material proportion for your reference:

一種。 混凝土:10%水泥,30%沙子,60%小石頭

b。 10%水泥,90%石材粉

C。 10%水泥,30%粉煤灰,60%石粉

10. Raytone company service

雷通 block machine manufacturer has a dedicated service team, both pre-sales service and after-sales service;

① For Pre-sales service,

we can provide professional suggestions like raw material batching, machine model selection, factory layout, factory profit analysis;

雷通 block machine manufacturer can recommend the suitable block machine model as per the buyer’ budget, daily capacity demand, etc

We have 24 hours online service

We can arrange the block machine factory visit and send invitation letter to the buyer;

Introduce the block machine details

② Sales service

Communicate with the buyer timely for block machine production schedule;

Quality control and supervision;

Block machine testing before delivery.

Shipping on time

③ After-sales service

The engineer will guide the buyer to do the installation of concrete block machine, operate, and trouble-shooting;

Skill support for the machine whole life

Recall the clients regularly to check if there is any technical need. Keep a good communication with the client;

WELCOME TO VISIT RAYTONE BLOCK MACHINE MANUFACTURER FOR FUTHER COOPERATION