- 04

- Mar

QT4-10 Igwe na-eme brik na-akpaghị aka

QT 4-10 Automatic Clay brik Ime Machine

1.Basic nkọwa nke igwe eji eme brik na-akpaghị aka

There are mainly QT4-10,QT5-10 QT7-10 QT10-10 Models

akpaka Igwe na-eme brik ụrọ working principle: clay bricks are forming via high pressure pressing; the pressure can differs from 50 ton, 100 tons 150ton, 200tons;

Ngwa ngwa nke brik ụrọ bụ ala, obere ciment.

The igwe brik ụrọ akpaka nwere ike ime brik dị iche iche na-ejikọta ọnụ, brik yinye, brik pavement, wdg site n’ịgbanwe ụdị brik dị iche iche.

Nnukwu ihe dị n’etiti igwe brik ụrọ akpaka na akpaka ihe mgbochi igwe bụ ụkpụrụ na-arụ ọrụ: igwe eji brik ụrọ na-akpaghị aka na-agbanye n’elu ma na-agbanye elu site na ala; mgbe igwe na-eme ihe mgbochi akpaka na-agbanye n’elu ma na-ama jijiji na ala; nke a bụ n’ihi na ihe odide akụrụngwa dị iche iche;

2. QT4-10 akpaghị aka Clay brik igwe eserese na-arụ ọrụ

① belt conveying machine #1

A na-eji igwe na-ebufe belt ebuga akụrụngwa nke ala na igwe ọzọ na-etipịa ihe.

| ogologo | 3M | ike: | 0.75KW |

| obosara | 75CM | Speed: | 2M / S |

| arọ: | 150KG |

② Onye na-egweri ala

A na-eji ihe nkedo ala na-etipịa ala n’ime obere ntụ ntụ;

| size | 1100 * 1100 * 1400mm | ike: | 5.5KW |

| ibu ibu | 120kg | ikike: | 500KG / Oge Awa |

③ Igwe na-ebufe belt #2

Nkọwapụta ahụ dịkwa na #1, nke a na-eji ebufe ala e gwepịara egwepịa n’ime igwe nyocha nke ala ọzọ

④ Igwe nyocha nke ala

| ike: | 3KW | ikike: | 480KG / H |

| ibu: | 320kg | dayameta: | 500mm |

⑤ Igwe na-ebufe eriri #3

Nkọwapụta ahụ dị na #1

A na-eji igwe na-ebufe belt a na-ebufe ala ekpuchiri elu n’ime igwekota pan;

⑥ JQ500 Pan igwekota

| dayameta | 1500mm | ike: | 7.5KW |

| elu: | 1300mm | ọsọ ọsọ: | 800L |

| arọ: | 500kg | mmepụta: | 500L |

| okirikiri ngwakọta: | 5 nkeji | arụpụtaghị | 10 cubic mita / elekere |

⑦ Igwe na-ebufe eriri

ngwa: eji ebufe ala si igwekota na akpaka ụrọ brik igwe

| ogologo: | 5M | ike: | 2.2KW |

| obosara: | 750mm | arọ: | 300KG |

⑧ Onye ọbịa akpaaka Igwe na-eme brik ụrọ

QT4-10 clay brick machine Specifications

| ike: | 7.5 kW | Pressure: | 31mpa |

| okirikiri ịkpụzi: | 7-10s | arọ: | 1600kg |

| usoro ọrụ: | nrụgide hydraulic | Dimension: | 2260 * 1500 * 2380mm |

| Ike kwa ụbọchị: | 9600 iberibe |

QT 4-10 Igwe brick Clay ike kwa ụbọchị

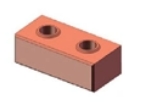

| Size (mm) | Photo | Pieces/Mould | Iberibe / Oge Awa | Iberibe/ụbọchị |

| 300 * 150 * 100 |

|

4 | 1200 | 9600 |

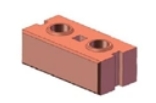

| 300 * 150 * 100 |

|

4 | 1200 | 9600 |

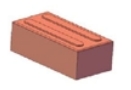

| 300 * 150 * 100 |

|

4 | 1200 | 9600 |

| 200 * 100 * 60mm |

|

4 | 1200 | 9600 |

| 200 * 100 * 60 |

|

4 | 1200 | 9600 |

3.Vidiyo na-arụ ọrụ nke QT4-10 automatic Clay brick Machine

4.Ndị ọzọ igwe brik ụrọ akpaka ụdị

① QT5-10 Igwe na-eme brik ụrọ nkọwa

| ike: | 15 kW | Pressure: | 16-22 mpa |

| okirikiri ịkpụzi: | 7-10s | arọ: | 1800kg |

| usoro ọrụ: | nrụgide hydraulic | Dimension: | 2520 * 1450 * 2500mm |

| Ike kwa ụbọchị: | 12000 iberibe |

QT 5-10 Igwe na-eme brik ụrọ ikike

| Size (mm) | Pieces/Mould | Iberibe / Oge Awa | Iberibe/ụbọchị |

| 300 * 150 * 100 | 5 | 1500 | 12000 |

| 200 * 100 * 60 | 5 | 1500 | 12000 |

② QT7-10 Igwe na-eme brik ụrọ nkọwa

| ike: | 15 kW | Pressure: | 31.5mpa |

| okirikiri ịkpụzi: | 7-10s | arọ: | 2000kg |

| usoro ọrụ: | nrụgide hydraulic | Dimension: | 2600*1800*220 0mm |

| Ike kwa ụbọchị: | 13440 iberibe |

QT 7-10 Igwe na-eme brik ụrọ ikike

| Size (mm) | Pieces/Mould | Iberibe / Oge Awa | Iberibe/ụbọchị |

| 300 * 150 * 100 | 7 | 1680 | 13440 |

| 200 * 100 * 60 | 7 | 1680 | 13440 |

③ QT10-10 Igwe na-eme brik ụrọ nkọwa

| ike: | 18 kW | Pressure: | 32mpa |

| okirikiri ịkpụzi: | 7-10s | arọ: | 2600kg |

| usoro ọrụ: | nrụgide hydraulic | Dimension: | 2860 * 1500 * 2380mm |

| Ike kwa ụbọchị: | 9600 iberibe |

QT 10-10 Igwe na-eme brik ụrọ ikike

| Size (mm) | Pieces/Mould | Iberibe / Oge Awa | Iberibe/ụbọchị |

| 300 * 150 * 100 | 10 | 3000 | 24000 |

| 200 * 100 * 60 | 10 | 3000 | 24000 |

5. Uru nke Automatic Clay brik Ime Machine

① Igwe brik ụrọ niile na-akpaghị aka na-eji sistemụ njikwa PLC nwere ọgụgụ isi na-arụkọ ọrụ na mmegharị hydraulic.

② Enwere ihuenyo mmetụ na igbe njikwa PLC, enwere ike gbanwee nrụgide site na ihuenyo mmetụ, ọ dị mfe.

③ A na-eji mgbapụta hydraulic vane dị elu nke nwere ịgbachi nkịtị dị ka isi mmanụ mmanụ iji nye nrụgide mmanụ siri ike na ịpị brik ụrọ, na ịpị hydraulic nwere ike ime obere mkpọtụ.

④ valvụ a ma ama solenoid valvụ na valvụ nha nha bụ akụkụ bụ isi nke sistemu nrụgide mmanụ,. valvụ abụọ ahụ na-eme ka njikwa hydraulic na-aga ngwa ngwa na n’ụzọ ziri ezi, ya mere brik ụrọ agwụla ga-enweta nrụgide zuru oke na nha ziri ezi;

⑤ The water cooling device will keep the hydraulic oil from high temperature, in order to let the clay brick machine work steadily.

⑥ The plunger mgbapụta na-eji airbag mwekota version, na-enye si ikuku si akụrụngwa; mgbe ahụ brik nwere ike ịdị larịị na otu.

⑦ Enwere mmanụ mmanụ abụọ n’elu ebu na otu mmanụ mmanụ n’okpuru ala ala, mgbapụta ahụ na-agbanye n’elu na ala n’otu oge, ya mere brik ahụ siri ike.

6. FAQ

① Kedu ka esi edozi elu brik mgbe ọ dị mkpa?

Enwere ike ịgbanwe elu brik site n’ịgbanwe ihe nkedo.

② Ala ole ka achọrọ maka igwe brik ụrọ na-akpaghị aka

For the workshop, 70 Square meters can meet the needs of these modes automatic clay brick machine,

But for the curing area, because different brick productivity needs different land area, so the automatic clay brick machine needs curing area from 1200 square meters to 2500 square meters;

③ How many workers are needed for automatic clay brick making machine?

5 Workers in total.

Otu onye ọrụ na-eburu ala n’elu igwe na-ebufe Belt maka ịzọpịa ọzọ.

Otu onye ọrụ na-ebu simenti na mmiri n’ime ngwa mixer

Otu onye ọrụ na-arụ ọrụ igwe brik na-akpaghị aka

Onye ọrụ abụọ na-ebu brik ọhụrụ site na: onye na-anata brik gaa ebe a na-agwọ ya

④ What is the ratio for making clay bricks

Material Ratio for Bricks: 5%-10% cement and 90%-95% soil

⑤ Kedu ọrụ ị na-ere mgbe ị na-enye

Anyị ga-enye ndị ahịa akwụkwọ ntuziaka ma wụnye vidiyo na anyị ga-ezigara injinia anyị na ebe ndị ahịa iji nyere ndị ahịa aka ịwụnye igwe na ndị ọrụ ụgbọ oloko

⑥ Gịnị bụ Raw Material Consumption n’ime otu ụbọchị

N’ebe a, anyị na-ewere brik 300 * 150 * 100mm dịka ọmụmaatụ ma kwado 8% ciment.

| Nha brik | 300 * 150 * 100mm lego brik |

| Ikike nke brik | 14400 brik n’otu ụbọchị |

| Oke ihe | 8% ciment na 92% ala |

| Oriri nke ciment | 6912 kg kwa ụbọchị |

| Oriri ala | 79488 kg kwa ụbọchị |

| Oriri mmiri | 2-3 tọn |

7. Foto nke brik ụrọ emere site na igwe eji eme brik na-akpaghị aka

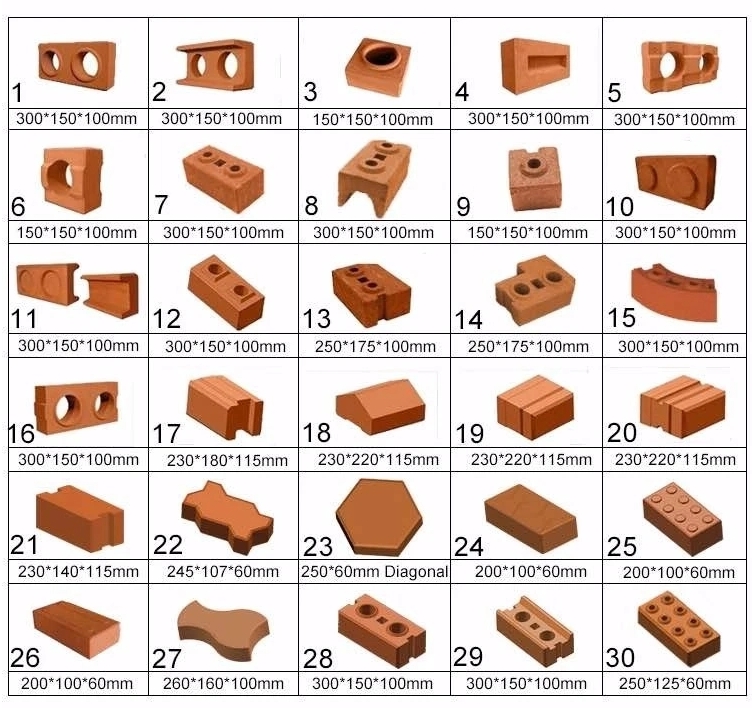

8. Clay brick samples

Onye ahịa nwere ike ịhọrọ ụdị brik ụrọ site na foto dị n’okpuru ebe a iji kwado ụdị brik

9. Igwe blọk nke Clay ntuziaka nhọrọ:

QTS2-25 igwe eji eme brik hydraulic ụrọ

M7MI TWIN Diesel Hydraform Soil Brick Machine

Nabata ịkpọtụrụ anyị ka anyị kwurịta banyere teknụzụ igwe brik ụrọ