- 29

- Jul

Application of Brick Machine

The construction industry continuously evolves, seeking efficient and sustainable methods for building infrastructure. Among the key innovations in this sector is the brick machine, a crucial piece of equipment that streamlines the production of bricks, making it faster and more cost-effective. Raytone Machinery, a leader in manufacturing brick machines, provides advanced solutions that cater to various construction needs. This article explores the applications of brick machines and how Raytone Machinery’s products are transforming the construction landscape.

Understanding Brick Machines

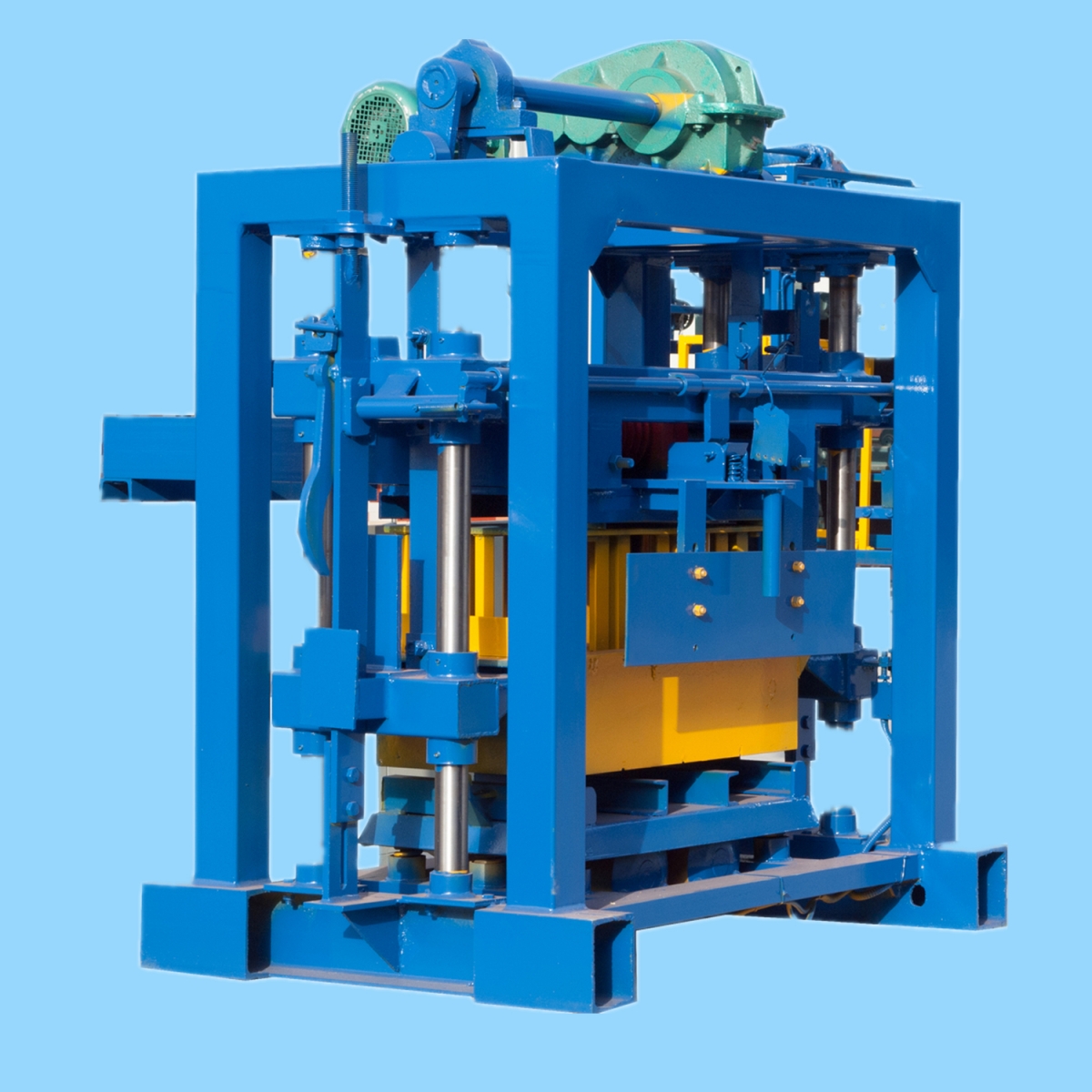

A brick machine, also known as a brick-making machine, is designed to produce bricks from raw materials like clay, fly ash, sand, and cement. The machine compresses these materials into bricks of various shapes and sizes, depending on the mold used. Brick machines can be categorized into manual, semi-automatic, and fully automatic models, each offering different levels of automation and production capacity.

QT4-10 Automatic Clay Brick Making Machine

QTS2-40 Manual Clay Brick Making Machine

M7MI TWIN Diesel Hydraform Soil Brick Machine

Key Applications of Brick Machines

1. Residential Construction

One of the primary applications of brick machines is in residential construction. Bricks are a fundamental building material used in constructing houses, apartments, and other residential structures. Raytone Machinery’s brick machines enable the efficient production of high-quality bricks that are essential for creating durable and aesthetically pleasing homes. The consistency and uniformity in brick size and shape achieved through these machines ensure that builders can maintain high standards of craftsmanship.

2. Commercial and Industrial Buildings

Brick machines also play a vital role in the construction of commercial and industrial buildings. These structures require bricks that can withstand heavy loads and environmental stresses. Raytone Machinery offers machines capable of producing strong, high-density bricks that meet the rigorous demands of commercial and industrial construction. These bricks are used in constructing office buildings, factories, warehouses, and retail spaces, providing the necessary structural integrity and durability.

3. Infrastructure Projects

Infrastructure projects, such as roads, bridges, and public facilities, also benefit from the use of brick machines. Bricks are often used in paving, lining drainage systems, and constructing barriers and retaining walls. Raytone Machinery’s advanced brick machines can produce a variety of brick types, including hollow bricks and pavers, which are particularly useful in infrastructure development. The machines’ ability to produce bricks in large quantities makes them ideal for meeting the high demands of such projects.

4. Environmental and Sustainable Construction

With growing awareness of environmental sustainability, there is an increasing demand for eco-friendly building materials. Brick machines from Raytone Machinery can use alternative materials like fly ash and other industrial waste, reducing the reliance on traditional clay bricks and minimizing environmental impact. These eco-friendly bricks contribute to sustainable construction practices, helping builders meet green building standards and reduce the carbon footprint of their projects.

Advantages of Raytone Machinery’s Brick Machines

Raytone Machinery is known for its innovative and reliable brick machines, which offer several advantages:

- Efficiency and Speed:

The machines are designed to produce bricks quickly and efficiently, significantly reducing construction timelines.

- Quality and Consistency:

Raytone Machinery’s brick machines ensure uniformity in brick size and shape, enhancing the overall quality of the construction.

- Versatility:

The machines can produce various types of bricks, including hollow, solid, and decorative bricks, catering to diverse construction needs.

- Cost-Effectiveness:

By enabling the on-site production of bricks, these machines help reduce transportation costs and provide significant savings on building materials.

Conclusion

The application of brick machines in the construction industry is vast and varied, encompassing residential, commercial, industrial, and infrastructure projects. Raytone Machinery’s advanced brick machines provide a reliable solution for producing high-quality bricks efficiently and cost-effectively. By leveraging the capabilities of these machines, builders can enhance their construction processes, improve project outcomes, and contribute to sustainable building practices.