- 13

- Jan

QT4-28 Hollow Block Making Machine

QT4-28 Maszyna do produkcji pustaków; ONE BUTTON BLOCK FORMING MACHINE.

1. QT4-28 Maszyna do produkcji pustaków Generally Description:

QT4-28 Maszyna do produkcji pustaków is improved from Ręczna maszyna blokująca QT4-40 . the difference is there is a hopper on the block making machine, so the QT4-28 maszyna do produkcji pustaków, can be matched with a belt conveying machine to conveying raw materials into the block machine hopper; another improvement is adding the raw materials distributing device to improve the working efficiency. so the Maszyna do produkcji bloków QT4-28 size is bigger and can save one labor than QT4-40 Manual Block Machine.

Pandemia Maszyna do produkcji bloków QT4-28 control PLC is almost full automatic (just need to press one button, the block will be formed ), so its operation is easy but output is big. So this this QT4-28 hollow block machine is also called ONE BUTTON BLOCK FORMING MACHINE.

QT4-28 Maszyna do produkcji pustaków is also vibrating via vibration motors like other manual block machine.

QT4-28 Maszyna do produkcji pustaków line price range is from 7900USD to 12000 USD.

QT4-28 Maszyna do produkcji pustaków daily productivity is 4114 pieces of 8 inch hollow blocks.

2. Basic Requirements for Start Up QT4-28 Maszyna do produkcji pustaków; ONE BUTTON BLOCK FORMING MACHINE;

| Powierzchnia terenu | Mierniki kwadratowe 300 | Konsumpcja wody | 2.4 t/dzień |

| Obszar warsztatu | Mierniki kwadratowe 30 | Napięcie i częstotliwość energii elektrycznej | 220V/380V/415V;50HZ/60HZ |

| Ilość pracy | pracownicy 3 | Pobór energii | 26.5 KW*8 Hours=212 KWH; |

| Zużycie cementu | 7.05 ton dziennie | Zużycie piasku | 28.5 ton dziennie |

| Zużycie kruszonych kamieni | 35.55 ton dziennie |

3. Each machine for QT4-28 Hollow Block Making Machine linia; ONE BUTTON BLOCK FORMING MACHINE

(1) JQ500 concrete mixer for QT4-28 Hollow Block Making Machine

| Pojemność karmienia | 750L | Pojemność rozładunku | 500L |

| Głębokość | 0.5m | Moc silnika | 11kw |

| Całkowity rozmiar | 1500 l * 1500 w * 1350 h (mm) | Średnica | 1500mm |

| Reduktor | 350 reducer/ truck rear axle gear | Waga | 800 kg |

(2) 6 Meters length belt conveying machine

Moc silnika: 1.5KW

Długość: 6 Metrów

Szerokość: 400mm

(3) QT4-28 Host block making machine; ONE BUTTON BLOCK FORMING MACHINE

QT4-28 is mechanical vibration type baking-free manual block machine.

It has 2 sets of bottom vibration motor of 3 KW, top vibration motor of 1 set 2.2 KW,

Raw materials distributing motor of 2.2 KW

Top mould fall down motor: 1.1KW

Block mould lift motor: 3.0 KW

push-pull mould by electric. dosing material at a time, easily operated, Regular production use 3 workers, one worker control mixer, one operate the host machine, two take charge of transporting formed blocks.

| (1) | Wymiar hosta | 2600 * 2000 * 2000mm | (6) | praca | pracownicy 4 |

| (2) | Waga maszyny hosta | 3.2T | (7) | Napięcie | dostosowane |

| (3) | Okres formowania | 25-28 | (8) | Całkowita wymagana moc maszyny | 26.5 kW |

| (4) | rozmiar palety | 850 * 550 * 20mm | (9) | Pojemność generatora diesla | 30KVA |

| (5) | Siła wibracji | 50KN | (10) | obszar warsztatu | 200 m2 |

(4) Manual block trolley

Used to transport the finished block to curing area.

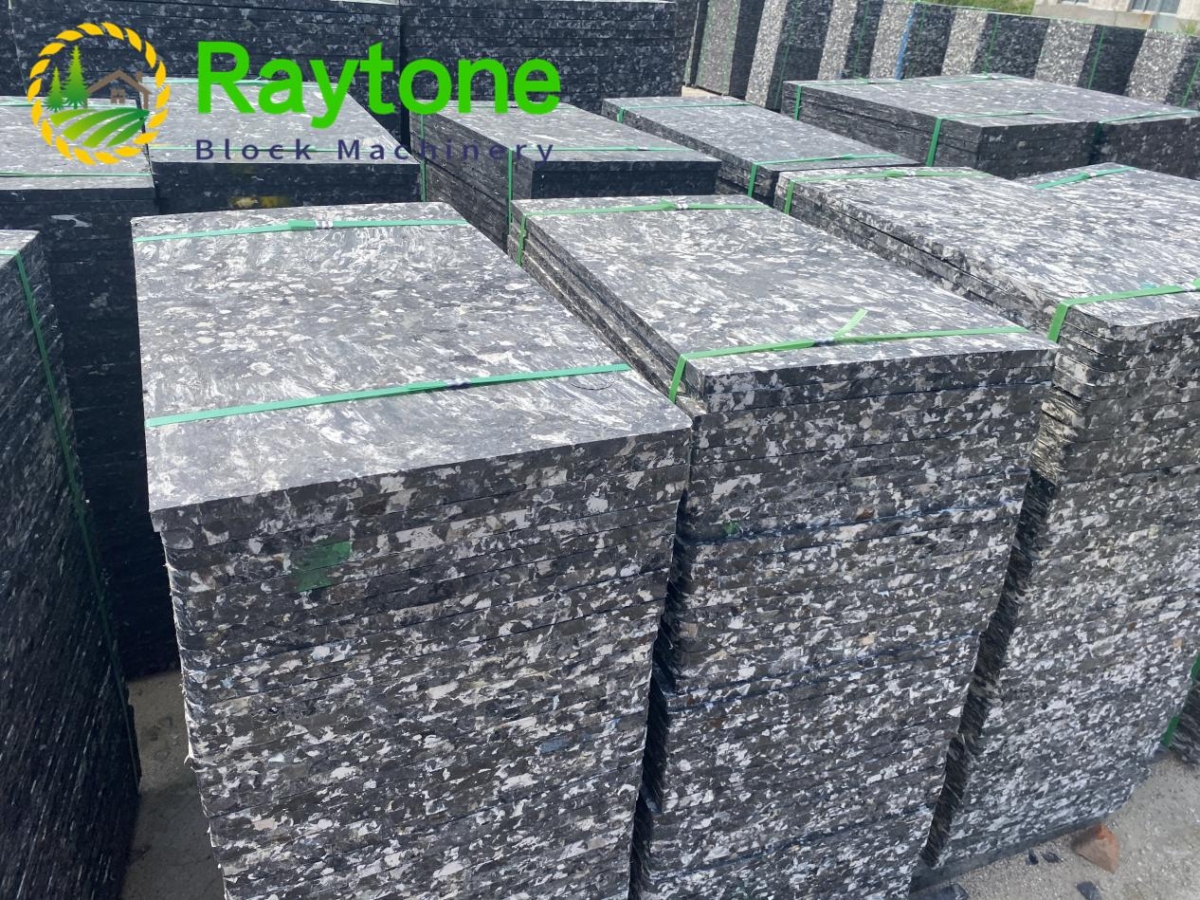

(5) GMT Brick pallets

The GMT brick pallet is used to hold the finished blocks. RAYTONE GMT brick pallet life can reach 8 to 10 years.

4. Daily productivity of QT4-28 Maszyna do produkcji pustaków

| QT4-28 Block Machine Theoretical production capacity | ||||||

| Rozmiar (L * W * H) (mm) | Zdjęcie | Okres formowania (S) | szt./forma | Szt / godz | szt / 8 godzin | |

| (1) | pustak 400*250*200 |

|

28 | 3 | 386 | 3086 |

| (2) | pustak 400*200*200 |

|

28 | 4 | 514 | 4114 |

| (3) | pustak 400*150*200 |

|

28 | 4 | 514 | 4114 |

| (4) | pustak 400*100*200 |

|

28 | 7 | 900 | 7200 |

| (5) | Cegła pełna 240*50*115 |

|

28 | 18 | 2314 | 18514 |

| (6) | Cegła porowata 240*115*90 |

|

28 | 9 | 1157 | 9257 |

| (7) | Krawężnik 500*200*300 |

|

28 | 1 | 129 | 1029 |

| (8) | Cegła do kostki brukowej w kształcie „I” bez koloru 200*163*60 |

|

28 | 6 | 771 | 6171 |

| (9) | Cegła do kostki brukowej w kształcie litery „S” bez koloru 225*112.5*60 |

|

28 | 9 | 1157 | 9257 |

| (10) | Holandia Cegła bez koloru 200*100*60 |

|

28 | 9 | 1157 | 9257 |

| (11) | Układarka kwadratowa bez koloru 250*250*60 |

|

28 | 3 | 386 | 3086 |

5. Working video of QT4-28 Maszyna do produkcji pustaków

6. Various Blocks and brick made from QT4-28 Maszyna do produkcji pustaków

7. FAQ

(1) Can this QT4-28 hollow block making machine make other types paver bricks, interlocking bricks?

Yes, this QT4-28 block machine can also make various shape and different size blocks brick under different block moulds.

(2) What is the raw materials and their formula for making the concrete blocks by QT4-28 hollow block making machine,

The raw materials are cement ,concrete ,sand ,fly ash ,construction waste, coal gangue, slag, mountain flour.

The formula of raw material is cement 8%-10% sand 30%-40% stone:50%-60%,about cement :sand : stone is1:4:5.

(3) What is the normal hollow block weight?

For the hollow block weight: 8 inch (400*200*200) block is 17KG, 6 inch (400*150*200) block is 13.5KG, 4 inch (400*100*200) block is 10KG.

8. QT4-28 maszyna do produkcji pustaków, Zalety:

(1) Easy installation and operation

The QT4-28 hollow block making machine just need to set up the belt conveying machine, and connect with power source, then can start operation.

(2) Low investment,

RAYTONE QT4-28 hollow block making machine price are competitive, and its price is much better than simple automatic QT4-25 block machine and Maszyna do produkcji bloków QT4-18

(3) Simple Design

The QT4-28 hollow block making machine is a simple structure,three is no pallet feeding device and block conveying out section, they pallet feeding is by hand, and finished blocks are take out by manual trolley.

(4) QTJ4-28 Semi-automatic brick making machine is specially designed for medium scale block project. It’s automatic materials feeding, distributing, brick forming. This model block machine is very economical, popular in developing countries.

9. RAYTONE block machine Company Service

① Professional concrete brick plant built up solution

② Hollow Block making machine quality supervision during production

③ Hollow Block making machine testing service before delivery.

④ Hollow Block making machine manufacture visit service.

⑤ Hollow Block machine shipment arrangement

⑥ Guide the client to operate the Hollow block making machine

⑦ Engineer to do oversea installation for Hollow block making machine

Please do not hesitate to contact RAYTONE block machine factory for good service