- 17

- Dec

QT12-15 automatisk blokkmaskin

QT12-15 AUTOMATIC BLOCK MACHINE DETALJERT INNLEDNING

1.QT12-15 Fully Automatisk blokkeringsmaskin Generelt beskrivelse

QT12-15 Fully Automatisk blokkeringsmaskin is with advanced design and technology. It has the biggest block Productivity for now, the blokker maskin is quipped with big power motors to give high pressure on the blocks, so strength blocks and bricks, so the block quality is excellent.

QT12-15 full automatic brick Machine produktivitet: 23040 stykker 8 tommers hule blokker per dag;

QT12-15 Fully Automatisk blokkeringsmaskin line Price Range: 50000 USD to 150000 USD;

2.QT12-15 Automatisk mursteinmaskin line Basic requirements for Brick Plant Start:

følgende informasjon for QT12-15 murstein maskin er teoretisk for referanse, de virkelige produksjonsdataene på stedet kan være små forskjellige avhengig av forskjellige råvarer osv.

| Land areal | 2500-6500 kvadratmeter | Vannforbruk | 14.4 T/dag |

| Verkstedområde | 200 kvadratmeter | Elektrisitet Spenning & Frekvens | 220V/380V/415V; 50HZ/60HZ |

| Arbeidsmengde | 6 arbeidere | Strømforbruk | 125.2KW*8 Timer= 1001.6KWH; |

| Sementforbruk | 37.8 tonn per dag | Sandforbruk | 151.2 tonn per dag |

| Forbruk av pukk | 187.2 tonn per dag |

3.Detaljert introduksjon av hver enkelt maskin fra QT12-15 fullstendig Automatisk blokkfremstillingsmaskin

(1) 100 Tons Cement Silo for QT12-15 Full automatisk blokkfremstillingsmaskin anlegg

| Kapasitet: | 100T | tank height | 9.6M |

| tankens diameter | 3.0M | cone height | 2.5M |

| leg height | 2M | total Height | 15.1M |

Some country may only have the cement in bags, not having bulk cement, so the cement silo is optional equipment. And for countries have bulk cement, the client can choose one or two sets cement silo as per their daily block capacity.

For the cement silos, there are two models, the one whole unit cement silo, which no need to be assembled at site; and split cement silo, which needs to be assembled at construction site; some Client may prefer the whole one unit cement silo, no need to install them one piece by one piece at site, but the one unit cement silo is taking much room for transport, its transport cost is much more, so client can consider the which is better for them.

(2) 8 meters Length cement screwing machine for QT12-15 full automatisk blokkmaskin

Length : 8 Meters, Power: 11KW; the diameter: 219mm

or Length: 6 Meters, Power: 7.5KW; the diameter: 219mm

The cement screwing machine is used to screw the cement from cement silo to the cement scale, which is installed on the JS750 concrete mixer;

(3) cement scale for QT12-15 full automatisk blokkmaskin

The cement scale is installed on the concrete mixer, it can weigh 150KG per batch, after weighing, the cement is discharged into concrete mixer directly, this will make the Andelen nøyaktig

(4) PLD1200 three hopper batching machine for QT12-15 full automatisk blokkmaskin

| Veie volum | 1.2CBM | Produktivitet | 60m3 / H |

| Maksimal veiing | 2000KG | Storing Volume | 2.2CBM*3 |

| Fôringshøyde | 2800MM | Aggregerte typer | 3 typer |

| Partnernøyaktighet | ± 2% | Belt conveying speed | 1.25m / s |

| makt | 3kw * 4 | Dimensjon: | 8830 * 2100 * 3300mm |

| Maskinvekt | 4000kg |

(5 XNUMX) 7 meters length fast belt conveying machine for QT12-15 full automatisk blokkmaskin

Length: 7000mm; width: 500mm, power: 2.2KW; cycloidal needle wheel type motor;

(6)JS750 Concrete Mixer for QT12-15 automatisk mursteinsmaskin

| Ladevolum | 1200L | Utladningsvolum | 750L |

| Aggregate Size: | ≤60 / 80 mm | Kapasitet | 35 Cubic meters/hour |

| Arbeidssirkel | 60S | Blandingshastighet | 35R / M |

| pumpemotor | 1.1kw | Blandeblad | 2 * 8 |

| blandemotor | 30KW | Dimensjon | 4550 * 2250 * 2450mm |

| Maskinvekt | 5500kg |

Det er to modeller av JS750 betongblander, den ene er med heistrakt, den andre er uten heistrakt, JS750 betongblander uten heis bruker hurtigbeltetransportmaskin for å mate råvarer inn i blanderen;

(7) Integrated control System for batching ang mixing Machine of QT12-15 full automatic block machine

This control panel is to join the concrete mixer and concrete batching machine to operate together, it can save one operator; it can be put at the side of the host brick machine PLC control panel, one operator can operate the whole brick making machine line. This is an optional part, client can choose accordingly.

(8) Host QT12-15 Stor automatisk blokkmaskin

<1> The main parameters of QT12-15 big Automatic block machine

| Dimensjon på vertsmaskin | 9400 * 3060 * 2980mm | vannforbruk | 14T / dag |

| Vekt på vertsmaskinen | 12.5T | Spenning | tilpasset |

| Støpeperiode | 12-20S | Total nødvendig maskinkraft | 107.8 |

| pallestørrelse | 1400 * 900 * 30mm | Diesel Genset kapasitet | 120KVA |

| Vibrasjonskraft | 100KN | verkstedområde | 250-300 m2 |

| arbeid | 3 | Land areal | 2500-6500 m2 |

<2> Motor power:

Vibrasjonsmotoreffekt: 11KW*2 (kunden kan også velge å bruke 4 stykker 5.5KW vibrerende motorer)

Hydraulisk stasjons motoreffekt: 22KW

Råstoffutslippsmotor: 2.2KW

Råstofffordelingsmotor: 4KW

Vertsblokkmaskin total effekt: 50.2 KW

<3> Blokker maskin ramme is made of high-strength steel and special welding technology, the machine frame is strong enough for the vibrating;

<4>Adopting synchronization mould lifting structure, the shaft sleeves are using cooper inside, so its life is as long as 10 years.

<5> raw materials Distribution system: the motor for Rods Swinging is 4 KW, enough power with the advance design can distribute the raw materials very evenly and fast;

<6> Vibration system: RAYTONE blokkmaskinfabrikk is using big power motor to make the blocks or bricks have enough vibration force and pressing force; and because RAYTONE PLC control panel is equipped with frequency converter, the electric motors vibrating frequency can be changed automatically, it has low frequency when raw materials distributing into block mould, high frequency when vibrating, So the concrete can be fully liquidation and exhausted in 2 to 3 seconds to reach the high density, this will make the blocks high density.

Also the Lengthened vibration shaft in the vibration box: We adopt lengthened vibration shaft and vibration box to make the vibration platform vibrate stably with more strong and less noise.Our vibration box is cast,won’t leak oil.

<7> PLC control panel for QT12-15 Automatisk blokkfremstillingsmaskin

The PLC control panel can use SIEMENS brand as optional.

RAYTONE mursteinsmaskinfabrikk also installed the frequency converter to change the vibration frequency and vibration time easily from the PLC panel, and also installed the electricity resister to protect the PLC control panel;

RAYTONE PLC control panel has automatic self-diagnosis function, it can clearly show all the faults and its happening location, to let the operator find it easily and solve it.

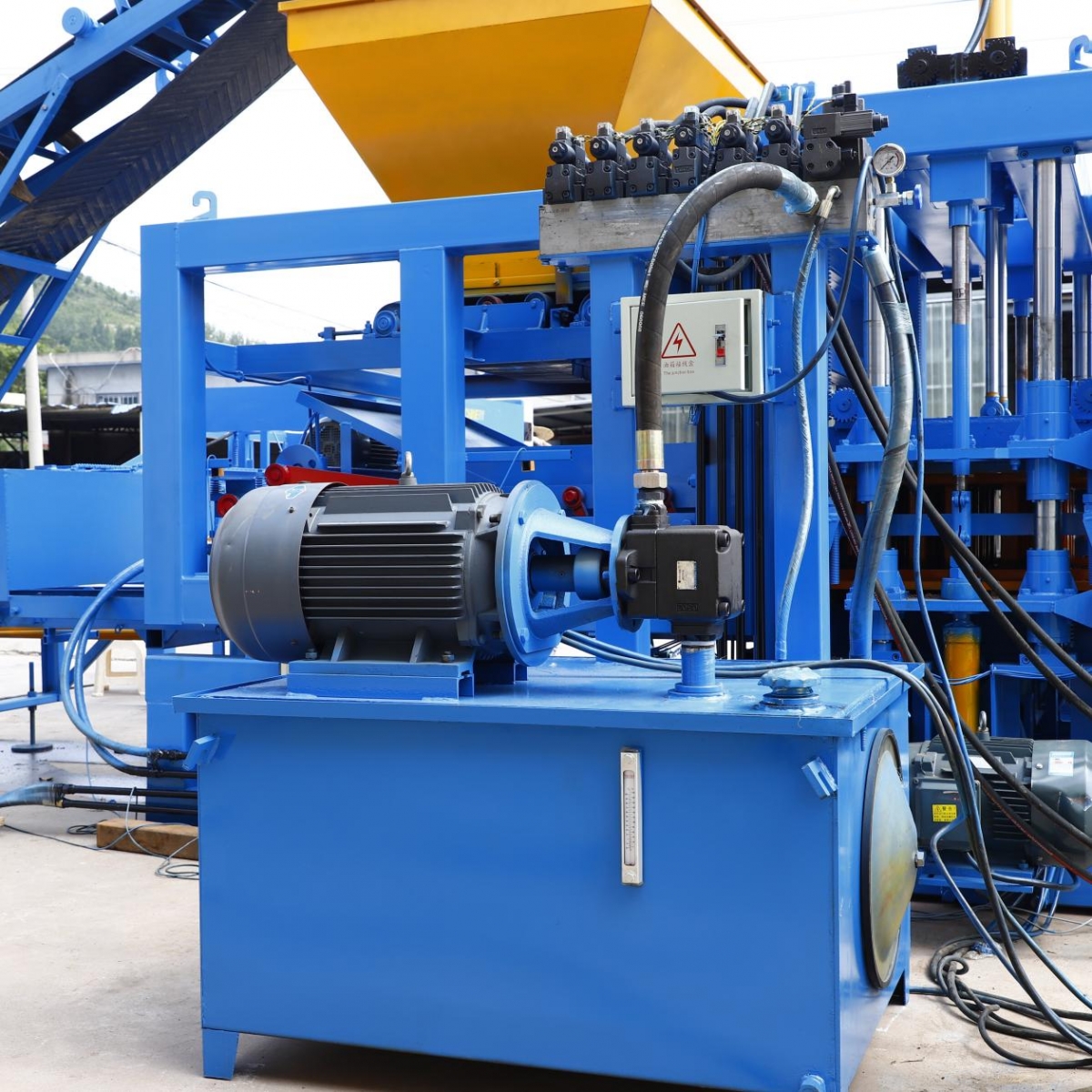

<8> Hydraulic Station for QT12-15 full automatisk blokkfremstillingsmaskin

RAYTONE mursteinsmaskinfabrikk is using the CYLYCA brand electromagnetic valves as standard, the Japan YUKEN brand valves can also be an optional.

The hydraulic station power is using 22KW motor; Client can also choose to use SIEMENS brand motors as optional, just need extra cost;

Hydraulic station is equip with water cooling system to keep the hydraulic tank oil not too much high temperature to affect the movements efficiency.

<9> Block Moulds for QT12-15 Automatisk betongblokkmaskin

All the block moulds are using 65 high manganese steel as raw materials, via Cutting, Welding, Machining, heat treatment, Carbonizing, etc , the block moulds life can reach one hundred thousand times;

(9) color feeding section for QT12-15 fully automatic concrete block machine

The color feeding machine is with hopper, it is fed by a 4 meters belt conveying machine,the pigments and fine sand are mixed in a JQ350 concrete mixer;

(10) Double Pallet Blocks Stacking Machine for QT12-15 Automatisk betongblokkmaskin

The block stacking machine is normally two-pallet stacking at the same time; Client can also choose three-pallet stacking machine to improve the stacking efficiency.

The stacking machine power is 3KW, 1.5kw for lift motor, 1.5KW for walking motor.

(11) Pallet Loading Machine for QT12-15 Automatisk betong murstein maskin

The pallet loading machine electric power is 5.2KW, it is used for loading the brick pallet into the pallet feeding machine of QT12-15 host brick machine, it can save 1 workers using this pallet loading machine.

(12) GMT brick Pallets for QT12-15 automatisk mursteinsmaskin

De GMT blokkpall is made from the leftovers of car inner roof decorations, seats and some adhesive etc. It is like PVC murstein pall , but better performance and cheap cost than PVC mursteinspall, it is strong enough for block machine, life can be 6-8 years.

(13) Blocks from QT12-15 fully automatisk blokkfremstillingsmaskin

4.Capacity of different blocks models under QT12-15 Blokkfremstillingsmaskin

| QT12-15 block production capacity | ||||||

| Størrelse (LxBxH) (mm) | Formingsperiode (S) | Bilde | Stk/ Form | Stk / time | Stk/ 8 timer | |

| (1) | hul blokk 400*250*200 | 15 |

|

10 | 2400 | 19200 |

| (2) | hul blokk 400*200*200 | 15 |

|

12 | 2880 | 23040 |

| (3) | hul blokk 400*150*200 | 15 |

|

16 | 3840 | 30720 |

| (4) | hul blokk 400*100*200 | 15 |

|

24 | 5760 | 46080 |

| (5) | Solid murstein 240*50*115 | 15 |

|

65 | 15600 | 124800 |

| (6) | Porøs murstein 240*115*90 | 15 |

|

30 | 7200 | 57600 |

| (7) | Kantstein 500*200*300 | 15 |

|

4 | 960 | 7680 |

| (8) | «I»-form utleggerstein 200*163*60 | 20 |

|

24 | 4320 | 34560 |

| (9) | “S” form utlegger murstein 225*112.5*60 | 20 |

|

30 | 5400 | 43200 |

| (10) | Holland Murstein 200*100*60 | 20 |

|

44 | 7920 | 63360 |

| (11) | Firkantet utlegger 250*250*60 | 20 |

|

15 | 2700 | 21600 |

5.Video viser hvordan QT12-15 Automatisk blokkeringsmaskin virker

6.Pakkeliste med QT12-15 Automatisk blokkeringsmaskin full linje

| 1 | 100 tonns sementsilo (valgfritt) | 1 sett | 10 | QT12-15 vert Murstein Maskin | 1 sett |

| 2 | Sement skruemaskin (valgfritt) | 1 sett | 11 | PLS kontrollpanel for verts mursteinsmaskin | 1 sett |

| 3 | Sementskala (valgfritt) | 1 sett | 12 | Hydraulisk stasjon | 1 sett |

| 4 | PLD1200 Betongdoseringsmaskin | 1 sett | 13 | Blokktransportør Maskin | 1 sett |

| 5 | 7M båndtransportmaskin | 1 sett | 14 | Stablemaskiner for blokker | 1 sett |

| 6 | JS750 Betongblander | 1 sett | 15 | JQ350 pigmentmikser | 1 sett |

| PLS kontrollpanel for betongblander og blandemaskin (valgfritt) | 1 sett | 16 | 6M båndtransportmaskin | 1 sett | |

| 7 | 8M båndtransportmaskin | 1 sett | 17 | pigmentfôringsmaskin | 1 sett |

| 8 | Lastemaskin for mursteinspall (valgfritt) | 1 sett | 18 | Manuelle traller | 2 sett |

| 9 | Pallmater for murstein | 1 sett | 19 | GMT murpall | 1200 stykker |

| 20 | Reservedeler | 1 sett |

7.Hvorfor velge RAYTONE blokker maskin?

(1) For the steel raw materials , RAYTONE blokker maskin is buying from China standard big steel factory to guarantee the raw materials quality first.

(2) For the welding, RAYTONE produksjon av blokker workers are very experienced and skilled. They have many years work experience in brick machine making.

(3) For the PLC control panel, client can choose Germany Siemens brand, the hydraulic electromagnetic valves, RAYTONE blokker maskin provides standard Taiwan CLYCA brand, but client can choose Japan YUKEN brand for optional, also for the sensor, RAYTONE blokker maskin is using Japan Omron brand;

(4) RAYTONE blokker maskin is using high manganese steel for block moulds, and strictly via Linear cutting , carbonized and heat treatment procedures, to make sure the block mould is with enough hardness for long life.

(5) RAYTONE blokker maskin design is advanced by reasonable raw material distributing system, Synchronous mould lift structure and vibration system;

8.Spørsmål og svar

(1) Can you make the block or brick drawings for client?

Yes, RAYTONE mursteinsmaskinfabrikk can provide all the block drawing to the client after purchase order is confirmed; the block mould drawings is to let the client to confirm the block moulds, this is important before production start.

(2) How do you guarantee your block machine quality?

Firstly, In the process of equipment production, we check the quality of equipment production at any time, carry out ex-factory testing before shipment to ensure product quality. RAYTONE produksjon av blokker has already more than 20 years experience in block machine making, we focus on every block machine quality to give our clients a good block machine with best advanced technology.

(3) What is the payment terms?

RAYTONE mursteinsmaskinfabrikk normally do 30% as deposit, balance before shipment by Telegraphic Transfer, and the irrevocable Letter of Credit at sight is also acceptable from some countries;

9. RAYTONE produksjon av blokker selskapstjenester

(1) Send the technicians to carry out the installation and debugging of equipment for the foreign users with compensation.and train local workers how to operated the block machine;

(2) If the client can send their workers to RAYTONE blokkmaskinfabrikk, we can train the workers in our factory.

(3) Teach and guide the worker to do the trouble-shooting in the daily production.

10. other related automatic block making machine

QT10-15 automatisk mursteinmaskin

QT8-15 Maskin for fremstilling av betongblokker

Welcome to contact RAYTONE produksjon av blokker for brick plant solution