- 17

- Dec

QT12-15 Máquina de Bloco Automática

QT12-15 AUTOMATIC BLOCK MACHINE INTRODUÇÃO DETALHADA

1.QT12-15 Fully Máquina de fazer bloco automática Descrição Geral

QT12-15 Fully Máquina de fazer bloco automática is with advanced design and technology. It has the biggest block Productivity for now, the máquina de bloco is quipped with big power motors to give high pressure on the blocks, so strength blocks and bricks, so the block quality is excellent.

QT12-15 full automatic brick Machine produtividade: 23040 peças de blocos ocos de 8 polegadas por dia;

QT12-15 Fully Máquina de bloco automática line Price Range: 50000 USD to 150000 USD;

2.QT12-15 Máquina Automática de Tijolo line Basic requirements for Brick Plant Start:

as seguintes informações para o QT12-15 máquina de tijolo é teoricamente para referência, os dados de produção do local real podem ser pequenos, diferentes de acordo com as diferentes matérias-primas, etc.

| área de pouso | 2500-6500 metros quadrados | Consumo de água | 14.4 t / dia |

| Área de oficina | Metros Quadrados 200 | Eletricidade, Tensão e Freqüência | 220V/380V/415V; 50HZ/60HZ |

| Quantidade de Trabalhos | Trabalhadores 6 | Consumo de energia | 125.2KW * 8 horas = 1001.6KWH; |

| Consumo de Cimento | 37.8 toneladas por dia | Consumo de areia | 151.2 toneladas por dia |

| Consumo de pedras trituradas | 187.2 toneladas por dia |

3.Introdução detalhada de cada máquina única de QT12-15 totalmente Máquina automática de fazer blocos

(1) 100 Tons Cement Silo for QT12-15 Full máquina de fazer bloco automático planta

| Capacidade: | 100T | tank height | 9.6M |

| diâmetro do tanque | 3.0M | cone height | 2.5M |

| altura da perna | 2M | total Height | 15.1M |

Some country may only have the cement in bags, not having bulk cement, so the cement silo is optional equipment. And for countries have bulk cement, the client can choose one or two sets cement silo as per their daily block capacity.

For the cement silos, there are two models, the one whole unit cement silo, which no need to be assembled at site; and split cement silo, which needs to be assembled at construction site; some Client may prefer the whole one unit cement silo, no need to install them one piece by one piece at site, but the one unit cement silo is taking much room for transport, its transport cost is much more, so client can consider the which is better for them.

(2) 8 meters Length cement screwing machine for QT12-15 full máquina de bloco automática

Length : 8 Meters, Power: 11KW; the diameter: 219mm

or Length: 6 Meters, Power: 7.5KW; the diameter: 219mm

The cement screwing machine is used to screw the cement from cement silo to the cement scale, which is installed on the JS750 concrete mixer;

(3) cement scale for QT12-15 full máquina de bloco automática

The cement scale is installed on the concrete mixer, it can weigh 150KG per batch, after weighing, the cement is discharged into concrete mixer directly, this will make the proporção preciso

(4) PLD1200 three hopper batching machine for QT12-15 full máquina de bloco automática

| Volume de Pesagem | 1.2CBM | Produtividade | 60M3 / H |

| Pesagem máxima | 2000KG | Storing Volume | 2.2CBM*3 |

| Altura de alimentação | 2800MM | Tipos agregados | Tipos 3 |

| Precisão de dosagem | ± 2% | Belt conveying speed | 1.25m / s |

| poder | 3kw * 4 | Dimensão: | 8830 2100 * * 3300mm |

| peso da máquina | 4000kg |

(5) 7 meters length fast belt conveying machine for QT12-15 full máquina de bloco automática

Length: 7000mm; width: 500mm, power: 2.2KW; cycloidal needle wheel type motor;

(6)JS750 Concrete Mixer for QT12-15 máquina automática de tijolos

| Volume de carga | 1200L | Volume de descarga | 750L |

| Aggregate Size: | ≤60 / 80mm | Capacidade | 35 Cubic meters/hour |

| Círculo de Trabalho | 60S | Velocidade de mistura | 35R / M |

| Motor da bomba | 1.1kw | Lâmina de Mistura | 2*8 |

| motor de mistura | 30KW | Dimensão | 4550 2250 * * 2450mm |

| peso da máquina | 5500kg |

Existem dois modelos de betoneira JS750, um é com tremonha de elevador, o outro é sem tremonha de elevador, a betoneira JS750 sem elevador está usando máquina de transporte de correia rápida para alimentar matérias-primas no misturador;

(7) Integrated control System for batching ang mixing Machine of QT12-15 full automatic block machine

This control panel is to join the concrete mixer and concrete batching machine to operate together, it can save one operator; it can be put at the side of the host brick machine PLC control panel, one operator can operate the whole brick making machine line. This is an optional part, client can choose accordingly.

(8) Host QT12-15 Grande Máquina de Bloco Automática

<1> The main parameters of QT12-15 big Automatic block machine

| Dimensão da máquina host | 9400 3060 * * 2980mm | consumo de água | 14 t / dia |

| Peso da máquina host | 12.5T | Voltagem | personalizado |

| Período de moldagem | 12-20S | Potência total necessária da máquina | 107.8 |

| tamanho da palete | 1400 900 * * 30mm | Capacidade do grupo gerador a diesel | 120KVA |

| Força de vibração | 100KN | área de oficina | 250-300 m2 |

| trabalho | 3 | Área de pouso | 2500-6500 m2 |

<2> Motor power:

Potência do motor de vibração: 11KW*2 (o cliente também pode optar por usar 4 peças de motores de vibração de 5.5KW)

Potência do motor da estação hidráulica: 22KW

Motor de descarga de matérias-primas: 2.2KW

Motor de distribuição de matérias-primas: 4KW

Potência total da máquina do bloco host: 50.2 KW

Máquina de bloco quadro is made of high-strength steel and special welding technology, the machine frame is strong enough for the vibrating;

Adopting synchronization mould lifting structure, the shaft sleeves are using cooper inside, so its life is as long as 10 years.

raw materials Distribution system: the motor for Rods Swinging is 4 KW, enough power with the advance design can distribute the raw materials very evenly and fast;

Vibration system: RAYTONE fábrica de máquina de bloco is using big power motor to make the blocks or bricks have enough vibration force and pressing force; and because RAYTONE PLC control panel is equipped with frequency converter, the electric motors vibrating frequency can be changed automatically, it has low frequency when raw materials distributing into block mould, high frequency when vibrating, So the concrete can be fully liquidation and exhausted in 2 to 3 seconds to reach the high density, this will make the blocks high density.

Also the Lengthened vibration shaft in the vibration box: We adopt lengthened vibration shaft and vibration box to make the vibration platform vibrate stably with more strong and less noise.Our vibration box is cast,won’t leak oil.

<7> PLC control panel for QT12-15 Máquina automática de fazer blocos

The PLC control panel can use SIEMENS brand as optional.

RAYTONE fábrica de máquinas de tijolos also installed the frequency converter to change the vibration frequency and vibration time easily from the PLC panel, and also installed the electricity resister to protect the PLC control panel;

RAYTONE PLC control panel has automatic self-diagnosis function, it can clearly show all the faults and its happening location, to let the operator find it easily and solve it.

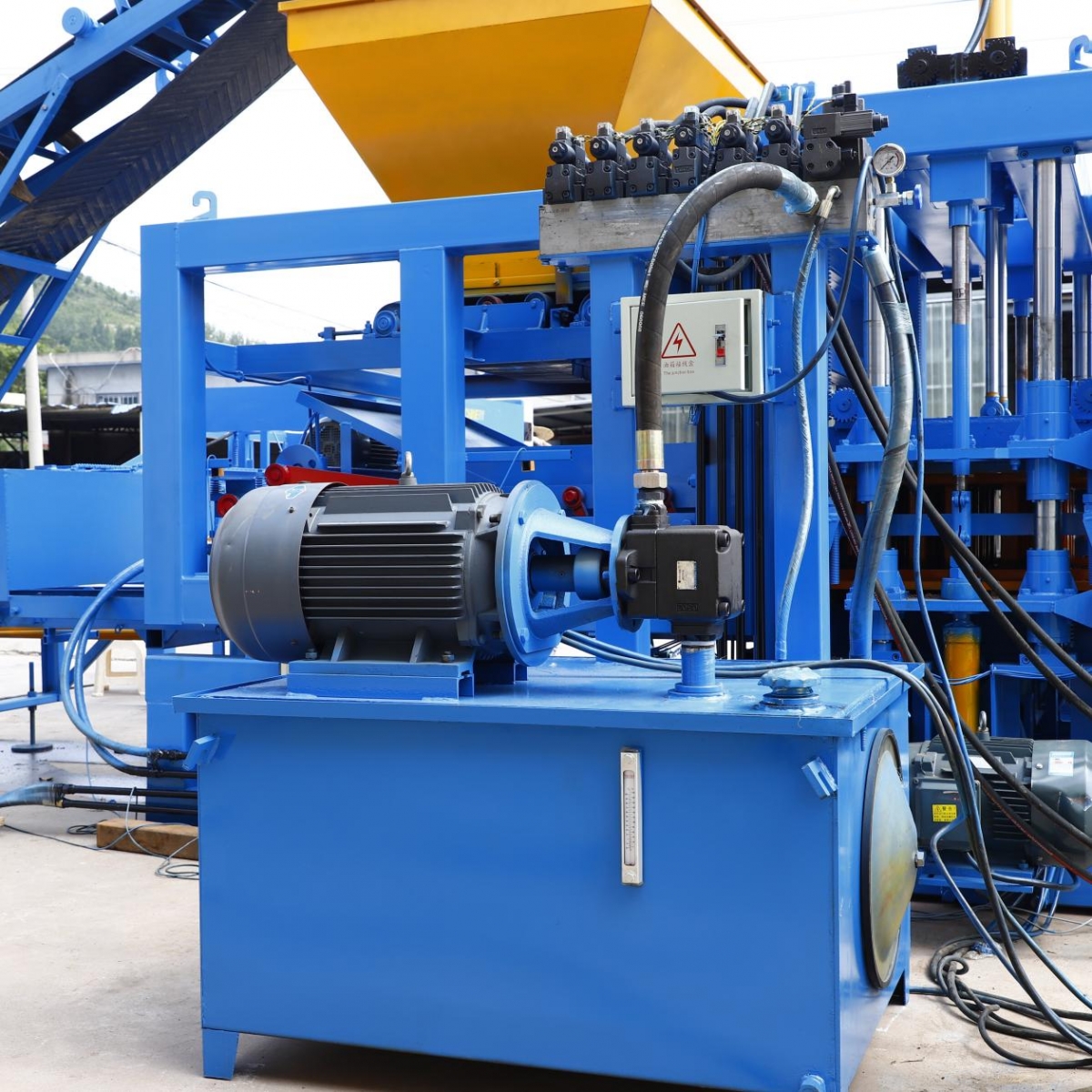

<8> Hydraulic Station for QT12-15 full máquina de fazer bloco automático

RAYTONE fábrica de máquinas de tijolos is using the CYLYCA brand electromagnetic valves as standard, the Japan YUKEN brand valves can also be an optional.

The hydraulic station power is using 22KW motor; Client can also choose to use SIEMENS brand motors as optional, just need extra cost;

Hydraulic station is equip with water cooling system to keep the hydraulic tank oil not too much high temperature to affect the movements efficiency.

<9> Block Moulds for QT12-15 Máquina automática para blocos de concreto

All the block moulds are using 65 high manganese steel as raw materials, via Cutting, Welding, Machining, heat treatment, Carbonizing, etc , the block moulds life can reach one hundred thousand times;

(9) color feeding section for QT12-15 fully máquina automática de bloco de concreto

The color feeding machine is with hopper, it is fed by a 4 meters belt conveying machine,the pigments and fine sand are mixed in a JQ350 concrete mixer;

(10) Double Pallet Blocks Stacking Machine for QT12-15 Máquina automática para blocos de concreto

The block stacking machine is normally two-pallet stacking at the same time; Client can also choose three-pallet stacking machine to improve the stacking efficiency.

The stacking machine power is 3KW, 1.5kw for lift motor, 1.5KW for walking motor.

(11) Pallet Loading Machine for QT12-15 Máquina automática de tijolos de concreto

The pallet loading machine electric power is 5.2KW, it is used for loading the brick pallet into the pallet feeding machine of QT12-15 host brick machine, it can save 1 workers using this pallet loading machine.

(12) GMT brick Pallets para QT12-15 máquina automática de tijolos

O GMT palete de blocos is made from the leftovers of car inner roof decorations, seats and some adhesive etc. It is like Palete de tijolos de PVC , but better performance and cheap cost than PVC palete de tijolos, it is strong enough for block machine, life can be 6-8 years.

(13) Blocks from QT12-15 fully máquina de fazer bloco automático

4.Capacity of different blocks models under QT12-15 Máquina de fazer blocos

| QT12-15 block production capacity | ||||||

| Tamanho (LxWxH) (mm) | Período de Formação (S) | Fotos | Pcs / Molde | Pcs / hora | Pcs / 8 horas | |

| (1) | bloco oco 400 * 250 * 200 | 15 |

|

10 | 2400 | 19200 |

| (2) | bloco oco 400 * 200 * 200 | 15 |

|

12 | 2880 | 23040 |

| (3) | bloco oco 400 * 150 * 200 | 15 |

|

16 | 3840 | 30720 |

| (4) | bloco oco 400 * 100 * 200 | 15 |

|

24 | 5760 | 46080 |

| (5) | Tijolo Sólido 240 * 50 * 115 | 15 |

|

65 | 15600 | 124800 |

| (6) | Tijolo Poroso 240 * 115 * 90 | 15 |

|

30 | 7200 | 57600 |

| (7) | Curbstone 500 * 200 * 300 | 15 |

|

4 | 960 | 7680 |

| (8) | Tijolo de pavimentação em forma de “I” 200 * 163 * 60 | 20 |

|

24 | 4320 | 34560 |

| (9) | Tijolo de pavimentação em forma de “S” 225 * 112.5 * 60 | 20 |

|

30 | 5400 | 43200 |

| (10) | Holland Brick 200 * 100 * 60 | 20 |

|

44 | 7920 | 63360 |

| (11) | Pavimentadora quadrada 250 * 250 * 60 | 20 |

|

15 | 2700 | 21600 |

5.Mostra de vídeo de como o QT12-15 Máquina de fazer bloco automática trabalho

6.Lista de embalagem de QT12-15 Máquina de bloco automática Linha completa

| 1 | Silo de cimento de 100 toneladas (opcional) | conjunto 1 | 10 | Host QT12-15 Máquina de tijolo | conjunto 1 |

| 2 | Parafusadeira de cimento (opcional) | conjunto 1 | 11 | Painel de controle PLC para máquina de tijolos host | conjunto 1 |

| 3 | Escala de cimento (opcional) | conjunto 1 | 12 | Estação Hidráulica | conjunto 1 |

| 4 | Máquina dosadora de concreto PLD1200 | conjunto 1 | 13 | Máquina de transporte de blocos | conjunto 1 |

| 5 | Máquina de transporte de correia 7M | conjunto 1 | 14 | Máquinas de empilhamento de blocos | conjunto 1 |

| 6 | Misturador de concreto JS750 | conjunto 1 | 15 | Misturador de Pigmentos JQ350 | conjunto 1 |

| Painel de controle PLC para betoneira e máquina dosadora (opcional) | conjunto 1 | 16 | Máquina transportadora de correia 6M | conjunto 1 | |

| 7 | Máquina transportadora de correia 8M | conjunto 1 | 17 | máquina de alimentação de pigmentos | conjunto 1 |

| 8 | Máquina de carregamento de paletes de tijolos (opcional) | conjunto 1 | 18 | Carrinhos manuais | conjunto 2 |

| 9 | Alimentador de paletes de tijolo | conjunto 1 | 19 | Palete de tijolos GMT | peças 1200 |

| 20 | Peças de reposição | conjunto 1 |

7.Por que escolher RAYTONE máquina de bloco?

(1) For the steel raw materials , RAYTONE máquina de bloco is buying from China standard big steel factory to guarantee the raw materials quality first.

(2) For the welding, RAYTONE fabricação de máquina de bloco workers are very experienced and skilled. They have many years work experience in brick machine making.

(3) For the PLC control panel, client can choose Germany Siemens brand, the hydraulic electromagnetic valves, RAYTONE máquina de bloco provides standard Taiwan CLYCA brand, but client can choose Japan YUKEN brand for optional, also for the sensor, RAYTONE máquina de bloco is using Japan Omron brand;

(4) RAYTONE máquina de bloco is using high manganese steel for block moulds, and strictly via Linear cutting , carbonized and heat treatment procedures, to make sure the block mould is with enough hardness for long life.

(5) RAYTONE máquina de bloco design is advanced by reasonable raw material distributing system, Synchronous mould lift structure and vibration system;

8.Perguntas frequentes

(1) Can you make the block or brick drawings for client?

Yes, RAYTONE fábrica de máquinas de tijolos can provide all the block drawing to the client after purchase order is confirmed; the block mould drawings is to let the client to confirm the block moulds, this is important before production start.

(2) How do you guarantee your block machine quality?

Firstly, In the process of equipment production, we check the quality of equipment production at any time, carry out ex-factory testing before shipment to ensure product quality. RAYTONE fabricação de máquina de bloco has already more than 20 years experience in block machine making, we focus on every block machine quality to give our clients a good block machine with best advanced technology.

(3) What is the payment terms?

RAYTONE fábrica de máquinas de tijolos normally do 30% as deposit, balance before shipment by Telegraphic Transfer, and the irrevocable Letter of Credit at sight is also acceptable from some countries;

9. RAYTONE fabricação de máquina de bloco serviços da empresa

(1) Send the technicians to carry out the installation and debugging of equipment for the foreign users with compensation.and train local workers how to operated the block machine;

(2) If the client can send their workers to RAYTONE fábrica de máquina de bloco, we can train the workers in our factory.

(3) Teach and guide the worker to do the trouble-shooting in the daily production.

10. other related automatic block making machine

QT10-15 Máquina Automática de Fabricação de Tijolos

QT8-15 máquina de fazer blocos de concreto

Welcome to contact RAYTONE fabricação de máquina de bloco for brick plant solution