- 07

- Jan

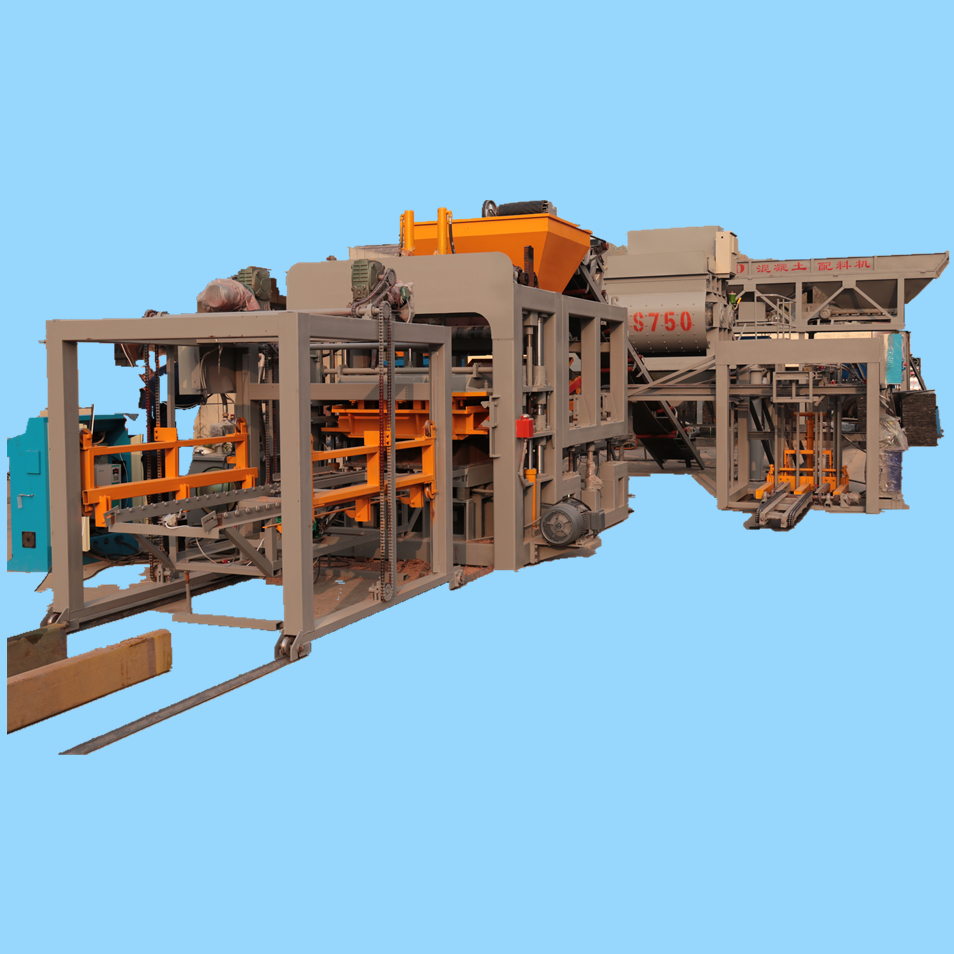

QT10-15 Automatische Ziegelherstellungsmaschine

QT10-15 Automatische Ziegelherstellungsmaschine

1.QT10-15 Automatische Ziegelherstellungsmaschine Allgemeine Beschreibung

QT10-15 is a Fully Automatische Ziegelherstellungsmaschine with big productivity. It is the second biggest automatische Ziegelmaschine model now.

QT10-15 automatic brick making Machine Produktivität: 19200 Stück 8-Zoll-Hohlblöcke pro Tag;

QT10-15 Automatic Brick making Machine Price Range: 50000 USD to 100000 USD;

2. QT10-15 Automatische Ziegelherstellungsmaschine line Basic requirements for start-up:

die folgenden Informationen für das QT10-15 automatische Ziegelmaschine dient theoretisch als Referenz, die Produktionsdaten des realen Standorts können aufgrund verschiedener Rohstoffe usw. geringfügig abweichen.

| Landfläche | 2500-6500 Quadratmeter | Wasserverbrauch | 12 T/Tag |

| Werkstattbereich | 200 Quadratmeter | Strom Spannung & Frequenz | 220V/380V/415V; 50HZ/60HZ |

| Arbeitsmenge | 6 Arbeiter | Energieverbrauch | 125.2 kW*8 Stunden = 1001.2 kWh; |

| Zementverbrauch | 31.5 Tonnen pro Tag | Sandverbrauch | 126 Tonnen pro Tag |

| Schotterverbrauch | 156 Tonnen pro Tag |

3. Detaillierte Vorstellung jeder einzelnen Maschine von QT10-15 vollständig Automatische Blockherstellungsmaschine

(1)The QT10-15 and QT12-15 Automatische Ziegelmaschine are all big capacity block making machine models, so their each single machines are almost same except the host brick machine.

Their first same sections are list out, which can refer to the following link for details:

①Raw materials storage section: cement silo and cement screwing machine for QT10-15 Automatic brick machine

Function: the 100 tons cement silo is used to store the bulk cement, if the client doesn’t have bulk cement locally, cannot use this cement silo, so it is an optional;

The 8 Meters length cement screwing machine is used to screw the cement from cement silo to the cement scale, which is installed on the JS750 concrete mixer;

The cement screwing machine is also an optional equipment, which is together with the cement silo.

② Concrete batching section: PLD1200 three hopper batching machine for QT10-15 Automatic brick machine

The PLD1200 concrete batching machine has two functions: one is used to store the raw materials , the other is to scale the different types of raw materials; this can give the blocks an accurate proportion, which make the blocks quality stable.

③ Concrete mixing section: JS750 twin shaft concrete mixer and cement scale for QT10-15 Automatic brick machine

Es gibt zwei Modelle des Betonmischers JS750, eines mit Elevatortrichter, das andere ohne Elevatortrichter, der Betonmischer JS750 ohne Aufzug verwendet eine schnelle Bandfördermaschine, um Rohstoffe in den Mischer einzuführen;

④ hydraulic station, this is to supply the hydraulic oil for cylinders of QT10-15 automatic brick making machine; the cooling water pump is installed on, which can cool the hydraulic oil to let hydraulic station work normally.

⑤ PLC control panel for QT10-15 Automatic brick machine

the PLC control panel is the key part in the block making machine line, RAYTONE block machine manufacture has his own PLC system, at the same time, the client can also choose the SIEMENS brand as optional.

⑥ paver brick surface coloring section: to give paver brick surface color

⑦ automatic stacking machine: used to stack the produced blocks, ready for transport to curing area.

⑧ brick pallet loading machine for QT10-15 Automatic brick machine, to supply the brick pallet to the Blockmaschinenpalette feeding machine, can save labor.

⑨ GMT Ziegelpalette, please refer to this link of GMT brick Pallet. The QT10-15 automatische Ziegelmaschine Ziegelpalette size is 1100*900*30mm , while QT12-15 automatic Ziegelmaschine is using 1400*900*30mm size brick pallet;

⑩ brick moulds for QT10-15 Automatische Ziegelmaschine,

RAYTONE brick moulds for hydraulische Blockmaschine are all via carburizing, Quenching, heat treatment, paver bricks also need linear cutting, the brick mould hardness can reach 60 HRC, life is 100 000 times;

(2) QT10-15 Host Ziegelmaschine Einführung

Motorleistung:

Vibrationsmotorleistung: 11KW * 2 (der Kunde kann auch 4 Stück 5.5-KW-Vibrationsmotoren verwenden)

Motorleistung der Hydraulikstation: 22KW

Rohstoff-Entladungsmotor: 2.2KW

Rohstoffverteilungsmotor: 4KW

Gesamtleistung der Hostblockmaschine: 50.2 KW

| QT10-15 Gastgeber Ziegelmaschine Haupttechnische Parameter | |||||

| (1) | Dimension des Hostcomputers | 9400 x 2860 x 2980 mm | (7) | Wasserverbrauch | 12T / Tag |

| (2) | Gewicht der Hostmaschine | 9.8T | (8) | Stromspannung | maßgeschneiderte |

| (3) | Formperiode | 12-20S | (9) | Gesamt benötigte Maschinenleistung | 103.3 |

| (4) | Palettengröße | 1100 x 900 x 30 mm | (10) | Leistung des Dieselgenerators | 120KVA |

| (5) | Vibrationskraft | 120KN | (11) | Werkstattbereich | 250-300 m2 |

| (6) | Arbeit | 5 bis 7 | (12) | Landfläche | 2500-6500 m2 |

Der QT10-15 automatic brick making machine Adopts more advanced material-feeding technology,material from the hopper fall into the mould case rapidly and evenly,

Machen Sie den Gewichtsfehler kleiner als ± 5%, den Intensitätsfehler kleiner als ≤ ± 15%.

4. Capacity of different blocks models under QT10-15 Ziegelherstellungsmaschine

| Produktionskapazität | ||||||

| Größe (LxBxH) (mm) | Umformzeit (S) | Foto | Stk./ Form | Stück / Stunde | Stk./ 8 Stunden | |

| (1) | Hohlblock 400*250*200 | 15 |

|

8 | 1920 | 15360 |

| (2) | Hohlblock 400*200*200 | 15 |

|

10 | 2400 | 19200 |

| (3) | Hohlblock 400*150*200 | 15 |

|

12 | 2880 | 23040 |

| (4) | Hohlblock 400*100*200 | 15 |

|

18 | 4320 | 34560 |

| (5) | Vollziegel 240*50*115 | 15 |

|

52 | 12480 | 99840 |

| (6) | Poröser Ziegelstein 240*115*90 | 15 |

|

24 | 5760 | 46080 |

| (7) | Bordstein 500*200*300 | 15 |

|

4 | 960 | 7680 |

| (8) | „I“-Form Pflasterstein 200*163*60 | 20 |

|

18 | 3240 | 25920 |

| (9) | „S“ Form Pflasterstein 225*112.5*60 | 20 |

|

24 | 4320 | 34560 |

| (10) | Holland-Ziegelstein 200*100*60 | 20 |

|

28 | 5040 | 40320 |

| (11) | Quadratischer Fertiger 250*250*60 | 20 |

|

12 | 2160 | 17280 |

5.Video show of how the QT10-15 Automatik Block, der Maschine herstellt Werk

6.Packliste von QT10-15 Automatische Blockiermaschine volle Linie

| 1 | 100 Tonnen Zementsilo (optional) | 1 Set | 10 | QT10-15 Host Brick making Machine | 1 Set |

| 2 | Zementschraubmaschine (optional) | 1 Set | 11 | SPS-Bedienfeld für Host-Brick-Maschine | 1 Set |

| 3 | Zementwaage (optional) | 1 Set | 12 | Hydraulikstation | 1 Set |

| 4 | PLD1200 Betonmischmaschine | 1 Set | 13 | Blockfördermaschine | 1 Set |

| 5 | 7M Bandfördermaschine | 1 Set | 14 | Maschinen zum Stapeln von Blöcken | 1 Set |

| 6 | JS750 Betonmischer | 1 Set | 15 | JQ350 Pigmentmischer | 1 Set |

| SPS-Bedienfeld für Betonmischer und Dosiermaschine (optional) | 1 Set | 16 | 6M Bandfördermaschine | 1 Set | |

| 7 | 8M Bandfördermaschine | 1 Set | 17 | Pigmentzuführmaschine | 1 Set |

| 8 | Ziegel-Paletten-Lademaschine (optional) | 1 Set | 18 | Handwagen | 2 Set |

| 9 | Palettenzuführung für Ziegel | 1 Set | 19 | GMT Ziegelpalette | 1200 Stücke |

| 20 | Ersatzteile | 1 Set |

7. Warum RAYTONE wählen? QT10-15 Brick making machine?

① The QT10-15 automatic brick machine is with high vibration and 120KN pressure, which can guarantee the produced blocks has high density and high strength.

② QT10-15 automatische Ziegelmaschine is with advanced technology on mechanical engineering and hydraulic systems. RAYTONE Ziegelmaschine mechanical design is improving at any time as per trouble shooting feedback from the users. RAYTONE hydraulic system is using CYLYCA brand electromagnetic valves, can give the brick machine a fast response for every movements.

③ Electric control system consists of imported color touch screen and programmed PLC with data input and output device, including safety logical control and trouble shooting system.

④ The PLC control panel is equipped with the frequency converter, this guarantee the automatische Ziegelmaschine work smooth, because the vibration motors are vibrating in different frequency, the frequency changes very often, during the raw materials are being feeding into the bottom mould, the vibration motors are vibration slowly, once the raw materials feeding procedure is finished, the vibration becomes fast and fiercely. So the frequency converter is used to guarantee the vibration works smooth and fast.

⑤ PLC intelligent control system which equipped with data input and output device,advanced safety logic and fault self-diagnosis system is adopted in full of the production procedure.

⑥ Vibration analyzing system:

detecting the vibration frequency, vibration amplitude,vibration acceleration and noise of the whole machine,so as to adjust the vibration to optimum efficiency

8. FAQ

(1) What is the raw materials formula for concrete blocks

There are several formula for different raw materials, the formula can be adjusted as per the client raw materials and their ratios;

The normal formula is as below:

① Standard concrete block: Cement 9-12%, sand 40%, stone 45%, water 3%

② Light concrete block: Cement 9-12%, slag 80-90%, water 3%

③ Cement 9-12%, sand 10-20%, stone 30-40%, slag 25-50%, water 3%

④ Cement 8%-10%, sand 30%-40%, stone 50%-60%

⑤ Cement 8%, sand 60%, Fly ash 30%, gypsum 2%.

(2) how to confirm which model Blockherstellungsmaschine is suitable for the client?

There are two ways to confirm, firstly if the client have a budget, can recommend the block machine model as per the budget;

Secondly is by the block making machine daily capacity:

The client need to confirm what size brick or block to produce, and how many per day

What is the local voltage and frequency.

What is the receiving port to quote the shipping cost.

Then we can provide an official quotation the the client.

9. RAYTONE Herstellung von Blockmaschinen Unternehmensdienstleistungen

① Professional Ziegelwerk built up solution

② Blockiermaschine quality supervision during production

③ Blockiermaschine testing service before delivery.

④ Block making machine manufacture visit service.

⑤ Maschine blockieren Versandvereinbarung

⑥ Guide the client to operate the Blockherstellungsmaschine

⑦ Engineer to do oversea installation for Blockherstellungsmaschine

WELCOME TO CONTACT RAYTONE BLOCK MACHINE MANUFACTURE FOR DETAILED QUOTATION