- 07

- Jan

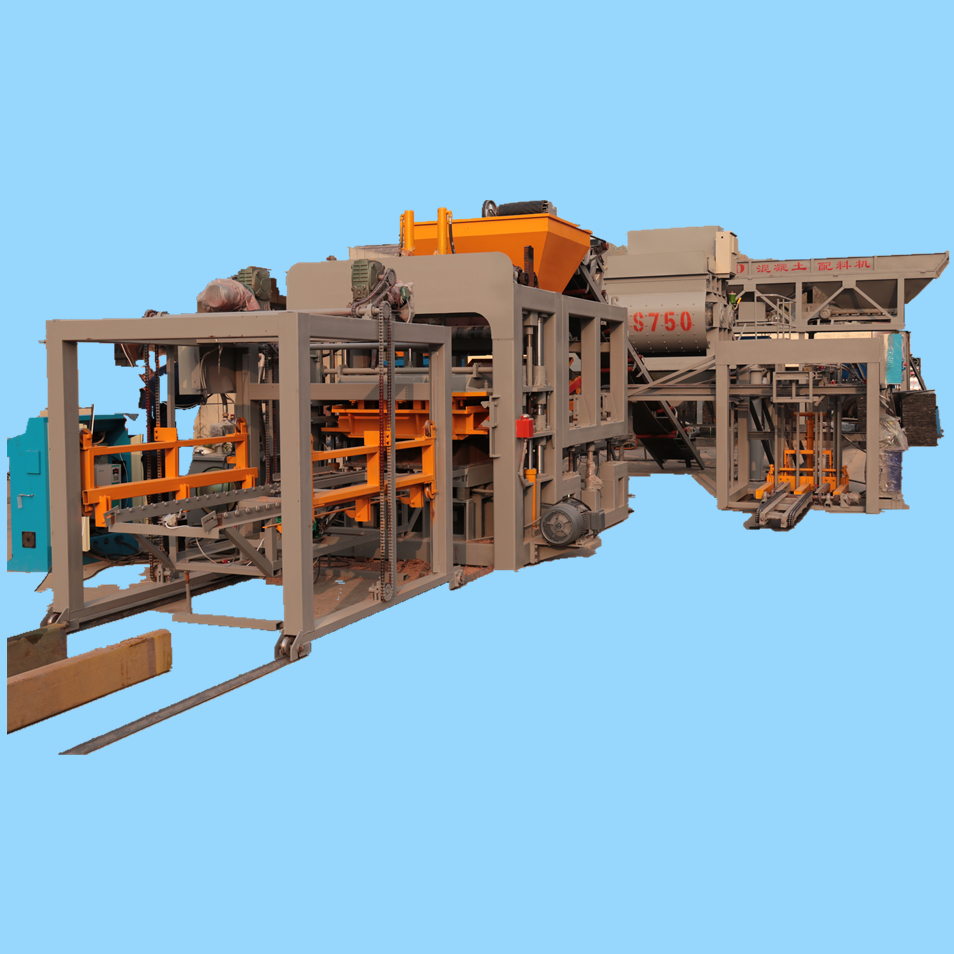

QT10-15全自動製磚機

1.QT10-15 自動製磚機 一般說明

QT10-15 is a Fully 自動製磚機 with big productivity. It is the second biggest 自動製磚機 model now.

QT10-15 automatic brick making Machine 產能:日產19200寸空心砌塊8塊;

QT10-15 Automatic Brick making Machine Price Range: 50000 USD to 100000 USD;

2. QT10-15 自動製磚機 line Basic requirements for start-up:

QT10-15的以下信息 自動製磚機 理論上僅供參考,實際現場生產數據可能因原材料不同等略有差異。

| 土地面積 | 2500-6500平方米 | 耗水量 | 12噸/天 |

| 車間面積 | 200平方米 | 電壓及頻率 | 220V/380V/415V; 50HZ/60HZ |

| 勞動力數量 | 6工人 | 能量消耗 | 125.2KW*8小時=1001.2 KWH; |

| 水泥消耗量 | 每天31.5噸 | 砂耗 | 每天126噸 |

| 碎石消耗 | 每天156噸 |

3. QT10-15各單機詳細介紹 自動砌塊機

(1)The QT10-15 and QT12-15 Automatic brick making machine are all big capacity block making machine models, so their each single machines are almost same except the host brick machine.

Their first same sections are list out, which can refer to the following link for details:

①Raw materials storage section: cement silo and cement screwing machine for QT10-15 Automatic brick machine

Function: the 100 tons cement silo is used to store the bulk cement, if the client doesn’t have bulk cement locally, cannot use this cement silo, so it is an optional;

The 8 Meters length cement screwing machine is used to screw the cement from cement silo to the cement scale, which is installed on the JS750 concrete mixer;

The cement screwing machine is also an optional equipment, which is together with the cement silo.

② Concrete batching section: PLD1200 three hopper batching machine for QT10-15 Automatic brick machine

The PLD1200 concrete batching machine has two functions: one is used to store the raw materials , the other is to scale the different types of raw materials; this can give the blocks an accurate proportion, which make the blocks quality stable.

③ Concrete mixing section: JS750 twin shaft concrete mixer and cement scale for QT10-15 Automatic brick machine

JS750混凝土攪拌機有兩種型號,一種是帶提昇機料斗,另一種是不帶提昇機料斗,JS750無提昇機混凝土攪拌機採用快速皮帶輸送機將原料送入攪拌機;

④ hydraulic station, this is to supply the hydraulic oil for cylinders of QT10-15 automatic brick making machine; the cooling water pump is installed on, which can cool the hydraulic oil to let hydraulic station work normally.

⑤ PLC control panel for QT10-15 Automatic brick machine

the PLC control panel is the key part in the block making machine line, RAYTONE block machine manufacture has his own PLC system, at the same time, the client can also choose the SIEMENS brand as optional.

⑥ paver brick surface coloring section: to give paver brick surface color

⑦ automatic stacking machine: used to stack the produced blocks, ready for transport to curing area.

⑧ brick pallet loading machine for QT10-15 Automatic brick machine, to supply the brick pallet to the 砌塊機托盤 feeding machine, can save labor.

⑨ GMT 磚托盤, please refer to this link of GMT brick Pallet. The QT10-15 自動製磚機 磚托盤 size is 1100*900*30mm , while QT12-15 automatic 製磚機 is using 1400*900*30mm size brick pallet;

⑩ brick moulds for QT10-15 Automatic brick making machine,

RAYTONE brick moulds for hydraulic block machine are all via carburizing, Quenching, heat treatment, paver bricks also need linear cutting, the brick mould hardness can reach 60 HRC, life is 100 000 times;

(2) QT10-15 Host 製磚機 介紹

電機功率:

振動電機功率:11KW*2(客戶也可選擇使用4台5.5KW振動電機)

液壓站電機功率:22KW

出料電機:2.2KW

原料分配電機:4KW

主機塊機總功率:50.2KW

| QT10-15 主持人 製磚機 主要技術參數 | |||||

| (1) | 主機尺寸 | 9400 * 2860 * 2980mm | (7) | 耗水量 | 12T /天 |

| (2) | 主機重量 | 9.8T | (8) | 電壓 | 定制 |

| (3) | 成型期 | 12-20S | (9) | 所需機器總功率 | 103.3 |

| (4) | 托盤尺寸 | 1100 * 900 * 30mm | (10) | 柴油發電機容量 | 120KVA |

| (5) | 振動力 | 120KN | (11) | 車間面積 | 250-300 m2 |

| (6) | 勞動 | 5 7到 | (12) | 土地面積 | 2500-6500 m2 |

QT10-15 automatic brick making machine Adopts more advanced material-feeding technology,material from the hopper fall into the mould case rapidly and evenly,

使重量誤差小於±5%,強度誤差小於≤±15%。

4. Capacity of different blocks models under QT10-15製磚機

| 生產能力 | ||||||

| 尺寸(LxWxH) (mm) | 成型期(S) | 上載照片 | 件/模具 | 個/小時 | 個/8小時 | |

| (1) | 空心砌塊400*250*200 | 15 |

|

8 | 1920 | 15360 |

| (2) | 空心砌塊400*200*200 | 15 |

|

10 | 2400 | 19200 |

| (3) | 空心砌塊400*150*200 | 15 |

|

12 | 2880 | 23040 |

| (4) | 空心砌塊400*100*200 | 15 |

|

18 | 4320 | 34560 |

| (5) | 實心磚240*50*115 | 15 |

|

52 | 12480 | 99840 |

| (6) | 多孔磚240*115*90 | 15 |

|

24 | 5760 | 46080 |

| (7) | 路緣石500*200*300 | 15 |

|

4 | 960 | 7680 |

| (8) | “I”字形攤舖磚200*163*60 | 20 |

|

18 | 3240 | 25920 |

| (9) | “S”形攤舖機磚225*112.5*60 | 20 |

|

24 | 4320 | 34560 |

| (10) | 荷蘭磚200*100*60 | 20 |

|

28 | 5040 | 40320 |

| (11) | 方形攤舖機250*250*60 | 20 |

|

12 | 2160 | 17280 |

5.Video show of how the QT10-15 IG自動按讃包月套餐 製磚機 作品

6.QT10-15裝箱單 自動砌塊機 全線

| 1 | 100噸水泥倉(可選) | 1集 | 10 | QT10-15 Host Brick making Machine | 1集 |

| 2 | 水泥打螺絲機(選配) | 1集 | 11 | 磚機主機PLC控制面板 | 1集 |

| 3 | 水泥秤(可選) | 1集 | 12 | 液壓站 | 1集 |

| 4 | PLD1200混凝土配料機 | 1集 | 13 | 砌塊輸送機 | 1集 |

| 5 | 7M皮帶輸送機 | 1集 | 14 | 砌塊堆垛機 | 1集 |

| 6 | JS750混凝土攪拌機 | 1集 | 15 | JQ350顏料混合機 | 1集 |

| 混凝土攪拌機和配料機PLC控制面板(可選) | 1集 | 16 | 6M皮帶輸送機 | 1集 | |

| 7 | 8M皮帶輸送機 | 1集 | 17 | 顏料上料機 | 1集 |

| 8 | 磚托盤裝載機(可選) | 1集 | 18 | 手推車 | 2集 |

| 9 | 磚托盤給料機 | 1集 | 19 | GMT 磚托盤 | 1200件 |

| 20 | 備件 | 1集 |

7. 為什麼選擇瑞通 QT10-15 Brick making machine?

① The QT10-15 automatic brick machine is with high vibration and 120KN pressure, which can guarantee the produced blocks has high density and high strength.

② QT10-15 自動製磚機 is with advanced technology on mechanical engineering and hydraulic systems. RAYTONE 製磚機 mechanical design is improving at any time as per trouble shooting feedback from the users. RAYTONE hydraulic system is using CYLYCA brand electromagnetic valves, can give the brick machine a fast response for every movements.

③ Electric control system consists of imported color touch screen and programmed PLC with data input and output device, including safety logical control and trouble shooting system.

④ The PLC control panel is equipped with the frequency converter, this guarantee the 自動磚機 work smooth, because the vibration motors are vibrating in different frequency, the frequency changes very often, during the raw materials are being feeding into the bottom mould, the vibration motors are vibration slowly, once the raw materials feeding procedure is finished, the vibration becomes fast and fiercely. So the frequency converter is used to guarantee the vibration works smooth and fast.

⑤ PLC intelligent control system which equipped with data input and output device,advanced safety logic and fault self-diagnosis system is adopted in full of the production procedure.

⑥ Vibration analyzing system:

detecting the vibration frequency, vibration amplitude,vibration acceleration and noise of the whole machine,so as to adjust the vibration to optimum efficiency

8. 常見問題

(1) What is the raw materials formula for concrete blocks

There are several formula for different raw materials, the formula can be adjusted as per the client raw materials and their ratios;

The normal formula is as below:

① Standard concrete block: Cement 9-12%, sand 40%, stone 45%, water 3%

② Light concrete block: Cement 9-12%, slag 80-90%, water 3%

③ Cement 9-12%, sand 10-20%, stone 30-40%, slag 25-50%, water 3%

④ Cement 8%-10%, sand 30%-40%, stone 50%-60%

⑤ Cement 8%, sand 60%, Fly ash 30%, gypsum 2%.

(2) how to confirm which model 製磚機 is suitable for the client?

There are two ways to confirm, firstly if the client have a budget, can recommend the block machine model as per the budget;

Secondly is by the block making machine daily capacity:

The client need to confirm what size brick or block to produce, and how many per day

What is the local voltage and frequency.

What is the receiving port to quote the shipping cost.

Then we can provide an official quotation the the client.

9. 雷通 砌塊機製造 公司服務

① Professional brick plant built up solution

② 製磚機 quality supervision during production

③ 製磚機 testing service before delivery.

④ Block making machine manufacture visit service.

⑤ 砌塊機 shipment arrangement

⑥ Guide the client to operate the 製磚機

⑦ Engineer to do oversea installation for 製磚機

WELCOME TO CONTACT RAYTONE BLOCK MACHINE MANUFACTURE FOR DETAILED QUOTATION