- 07

- Jan

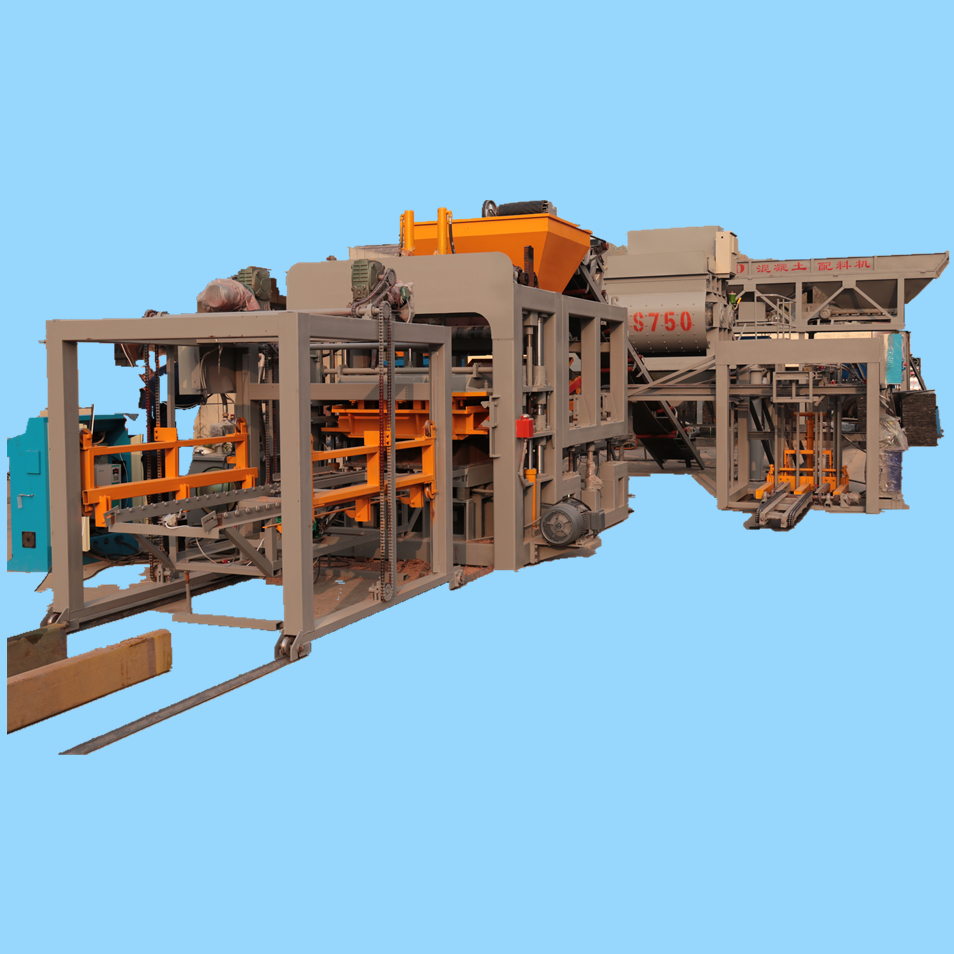

QT10-15 Otomatik Tuğla Makinası

QT10-15 Otomatik Tuğla Makinası

1.QT10-15 Otomatik Tuğla Yapma Makinesi Genel Açıklama

QT10-15 is a Fully Otomatik Tuğla Yapma Makinesi with big productivity. It is the second biggest otomatik tuğla yapma makinesi model now.

QT10-15 automatic brick making Machine üretkenlik: günde 19200 adet 8 inç içi boş blok;

QT10-15 Automatic Brick making Machine Price Range: 50000 USD to 100000 USD;

2. QT10-15 Otomatik Tuğla Yapma Makinesi line Basic requirements for start-up:

QT10-15 için aşağıdaki bilgiler otomatik tuğla yapma makinesi teorik olarak referans içindir, gerçek site üretim verileri, farklı hammaddelere vb. göre küçük farklı olabilir.

| arazi alanı | 2500-6500 Metrekare | Su tüketimi | 12 T/gün |

| Atölye alanı | 200 Metrekare | Elektrik Gerilimi ve Frekansı | 220V/380V/415V; 50HZ/60HZ |

| İşçilik Miktarı | 6 işçiler | Güç tüketimi | 125.2KW*8 Saat=1001.2 KWH; |

| Çimento Tüketimi | Günde 31.5 Ton | kum tüketimi | Günde 126 ton |

| kırma taş tüketimi | Günde 156 ton |

3. QT10-15’ten her bir makinenin ayrıntılı tanıtımı tamamen Otomatik blok makinesi

(1)The QT10-15 and QT12-15 Automatic brick making machine are all big capacity block making machine models, so their each single machines are almost same except the host brick machine.

Their first same sections are list out, which can refer to the following link for details:

①Raw materials storage section: cement silo and cement screwing machine for QT10-15 Automatic brick machine

Function: the 100 tons cement silo is used to store the bulk cement, if the client doesn’t have bulk cement locally, cannot use this cement silo, so it is an optional;

The 8 Meters length cement screwing machine is used to screw the cement from cement silo to the cement scale, which is installed on the JS750 concrete mixer;

The cement screwing machine is also an optional equipment, which is together with the cement silo.

② Concrete batching section: PLD1200 three hopper batching machine for QT10-15 Automatic brick machine

The PLD1200 concrete batching machine has two functions: one is used to store the raw materials , the other is to scale the different types of raw materials; this can give the blocks an accurate proportion, which make the blocks quality stable.

③ Concrete mixing section: JS750 twin shaft concrete mixer and cement scale for QT10-15 Automatic brick machine

JS750 beton mikserinin iki modeli vardır, biri asansörlü, diğeri asansörsüz, asansörsüz JS750 beton mikseri, hammaddeleri miksere beslemek için hızlı bantlı taşıma makinesi kullanıyor;

④ hydraulic station, this is to supply the hydraulic oil for cylinders of QT10-15 automatic brick making machine; the cooling water pump is installed on, which can cool the hydraulic oil to let hydraulic station work normally.

⑤ PLC control panel for QT10-15 Automatic brick machine

the PLC control panel is the key part in the block making machine line, RAYTONE block machine manufacture has his own PLC system, at the same time, the client can also choose the SIEMENS brand as optional.

⑥ paver brick surface coloring section: to give paver brick surface color

⑦ automatic stacking machine: used to stack the produced blocks, ready for transport to curing area.

⑧ brick pallet loading machine for QT10-15 Automatic brick machine, to supply the brick pallet to the blok makine paleti feeding machine, can save labor.

⑨ GMT tuğla palet, please refer to this link of GMT brick Pallet. The QT10-15 otomatik tuğla yapma makinesi tuğla palet size is 1100*900*30mm , while QT12-15 automatic tuğla yapma makinesi is using 1400*900*30mm size brick pallet;

⑩ brick moulds for QT10-15 Automatic brick making machine,

RAYTONE brick moulds for hidrolik blok makinesi are all via carburizing, Quenching, heat treatment, paver bricks also need linear cutting, the brick mould hardness can reach 60 HRC, life is 100 000 times;

(2) QT10-15 Host tuğla yapma makinesi giriş

Motor gücü:

Titreşim motor gücü: 11KW*2 (müşteri ayrıca 4 adet 5.5KW titreşimli motor kullanmayı da seçebilir)

Hidrolik İstasyon motor gücü: 22KW

Hammadde boşaltma motoru: 2.2KW

Motoru dağıtan hammaddeler: 4KW

Ana makine blok makinesi toplam gücü: 50.2 KW

| QT10-15 ev sahibi tuğla yapma makinesi Ana teknik parametreler | |||||

| (1) | Ana makinenin boyutu | 9400 * 2860 * 2980mm | (7) | su tüketimi | 12T / gün |

| (2) | Ana makinenin ağırlığı | 9.8T | (8) | Voltaj | özelleştirilmiş |

| (3) | Kalıplama dönemi | 12-20 | (9) | Toplam gerekli makine gücü | 103.3 |

| (4) | palet boyutu | 1100 * 900 * 30mm | (10) | Dizel Jeneratör kapasitesi | 120KVA |

| (5) | Titreşim kuvveti | 120KN | (11) | atölye alanı | 250-300 m2 |

| (6) | emek | 5 için 7 | (12) | Arazi alanı | 2500-6500 m2 |

The QT10-15 automatic brick making machine Adopts more advanced material-feeding technology,material from the hopper fall into the mould case rapidly and evenly,

ağırlık hatasını ±% 5’ten, yoğunluk hatasını ≤ ±% 15’ten az yapın.

4. Capacity of different blocks models under QT10-15 Brick Making Machine

| üretim kapasitesi | ||||||

| Boyut (UxGxY) (mm) | Şekillendirme Dönemi (S) | Fotoğraf | Adet/ Kalıp | Adet / Saat | Adet / 8 saat | |

| (1) | içi boş blok 400*250*200 | 15 |

|

8 | 1920 | 15360 |

| (2) | içi boş blok 400*200*200 | 15 |

|

10 | 2400 | 19200 |

| (3) | içi boş blok 400*150*200 | 15 |

|

12 | 2880 | 23040 |

| (4) | içi boş blok 400*100*200 | 15 |

|

18 | 4320 | 34560 |

| (5) | Masif Tuğla 240*50*115 | 15 |

|

52 | 12480 | 99840 |

| (6) | Gözenekli Tuğla 240*115*90 | 15 |

|

24 | 5760 | 46080 |

| (7) | Bordür 500*200*300 | 15 |

|

4 | 960 | 7680 |

| (8) | “I” şekilli finişer tuğlası 200*163*60 | 20 |

|

18 | 3240 | 25920 |

| (9) | “S” Şekilli Parke Tuğlası 225*112.5*60 | 20 |

|

24 | 4320 | 34560 |

| (10) | Hollanda Tuğla 200*100*60 | 20 |

|

28 | 5040 | 40320 |

| (11) | Kare Finişer 250*250*60 | 20 |

|

12 | 2160 | 17280 |

5.Video show of how the QT10-15 Otomatik Blok Yapma Makinesi çalışır

6.QT10-15’in ambalaj listesi Otomatik Blok Makinası Tam satır

| 1 | 100 ton Çimento silosu (opsiyonel) | 1 seti | 10 | QT10-15 Host Brick making Machine | 1 seti |

| 2 | Çimento Vidalama makinesi (opsiyonel) | 1 seti | 11 | Ana tuğla makinesi için PLC kontrol Paneli | 1 seti |

| 3 | Çimento terazisi (isteğe bağlı) | 1 seti | 12 | Hidrolik İstasyon | 1 seti |

| 4 | PLD1200 Beton harmanlama makinesi | 1 seti | 13 | Blok konveyör Makinası | 1 seti |

| 5 | 7M bant taşıma Makinası | 1 seti | 14 | Blok İstifleme Makinaları | 1 seti |

| 6 | JS750 Beton karıştırıcı | 1 seti | 15 | JQ350 Pigment Karıştırıcı | 1 seti |

| Beton karıştırıcı ve harmanlama makinesi için PLC kontrol paneli (opsiyonel) | 1 seti | 16 | 6M bantlı taşıma makinesi | 1 seti | |

| 7 | 8M bantlı taşıma makinesi | 1 seti | 17 | pigment besleme makinesi | 1 seti |

| 8 | Tuğla palet yükleme makinesi (opsiyonel) | 1 seti | 18 | Manuel arabalar | 2 seti |

| 9 | Tuğla Palet Besleyici | 1 seti | 19 | GMT tuğla palet | 1200 parçalar |

| 20 | Yedek parça | 1 seti |

7. Neden RAYTONE’u seçmelisiniz? QT10-15 Brick making machine?

① The QT10-15 automatic brick machine is with high vibration and 120KN pressure, which can guarantee the produced blocks has high density and high strength.

② QT10-15 otomatik tuğla yapma makinesi is with advanced technology on mechanical engineering and hydraulic systems. RAYTONE tuğla yapma makinesi mechanical design is improving at any time as per trouble shooting feedback from the users. RAYTONE hydraulic system is using CYLYCA brand electromagnetic valves, can give the brick machine a fast response for every movements.

③ Electric control system consists of imported color touch screen and programmed PLC with data input and output device, including safety logical control and trouble shooting system.

④ The PLC control panel is equipped with the frequency converter, this guarantee the otomatik tuğla makinesi work smooth, because the vibration motors are vibrating in different frequency, the frequency changes very often, during the raw materials are being feeding into the bottom mould, the vibration motors are vibration slowly, once the raw materials feeding procedure is finished, the vibration becomes fast and fiercely. So the frequency converter is used to guarantee the vibration works smooth and fast.

⑤ PLC intelligent control system which equipped with data input and output device,advanced safety logic and fault self-diagnosis system is adopted in full of the production procedure.

⑥ Vibration analyzing system:

detecting the vibration frequency, vibration amplitude,vibration acceleration and noise of the whole machine,so as to adjust the vibration to optimum efficiency

8. SSS

(1) What is the raw materials formula for concrete blocks

There are several formula for different raw materials, the formula can be adjusted as per the client raw materials and their ratios;

The normal formula is as below:

① Standard concrete block: Cement 9-12%, sand 40%, stone 45%, water 3%

② Light concrete block: Cement 9-12%, slag 80-90%, water 3%

③ Cement 9-12%, sand 10-20%, stone 30-40%, slag 25-50%, water 3%

④ Cement 8%-10%, sand 30%-40%, stone 50%-60%

⑤ Cement 8%, sand 60%, Fly ash 30%, gypsum 2%.

(2) how to confirm which model blok yapma makinesi is suitable for the client?

There are two ways to confirm, firstly if the client have a budget, can recommend the block machine model as per the budget;

Secondly is by the block making machine daily capacity:

The client need to confirm what size brick or block to produce, and how many per day

What is the local voltage and frequency.

What is the receiving port to quote the shipping cost.

Then we can provide an official quotation the the client.

9. RAYTON blok makine imalatı şirket hizmetleri

① Professional tuğla fabrikası built up solution

② Blok yapma makinesi quality supervision during production

③ Blok yapma makinesi testing service before delivery.

④ Block making machine manufacture visit service.

⑤ Blok makinesi shipment arrangement

⑥ Guide the client to operate the blok yapma makinesi

⑦ Engineer to do oversea installation for blok yapma makinesi

WELCOME TO CONTACT RAYTONE BLOCK MACHINE MANUFACTURE FOR DETAILED QUOTATION