- 22

- Mar

Molded pallet Compress wood pallet

Molded Pallet Compressed wood pallet

1.Compressed Wood Pallet Description:

Compressed wood pallet is a wooden pallet pressed out via high pressure moulding, it is used for logistic transport, it is one unit compressed pallet without any joints;

The compressed wood pallet is also called molded wooden pallet, The molded pallet is a new type of environmentally friendly tray made of high-quality wood chips, wood shavings and other plant fibers, dried, glued, and molded at a high temperature and high pressure.

the compressed wood pallet is very widely used in logistic transport now becuae it has many advantages;

2.Ang mga pakinabang ng compressed wood pallet

(1) Environmental protection: Utilize waste, improve the utilization rate of wood, realize recycling, recycling, reuse, and the recovery rate can reach 100%.

(2) One-time molding: no nail assembly is required, the surface is smooth, and the goods will not be scratched

(3) Fumigation-free: Sumusunod sa mga kinakailangan ng international ISP15. Mas maginhawa at mas mabilis ang fumigation-free, import at export customs clearance.

(4) Hindi madaling masunog: malakas na paglaban sa sunog

(5) Pagtitipid sa gastos: The price is more than 50% cheaper than the traditional conifer or broadleaf wood tray;

(6) Four-way fork: matutugunan nito ang mga pangangailangan ng iba’t ibang laki ng manual hydraulic truck at forklift nang sabay-sabay, at maginhawa itong gamitin.

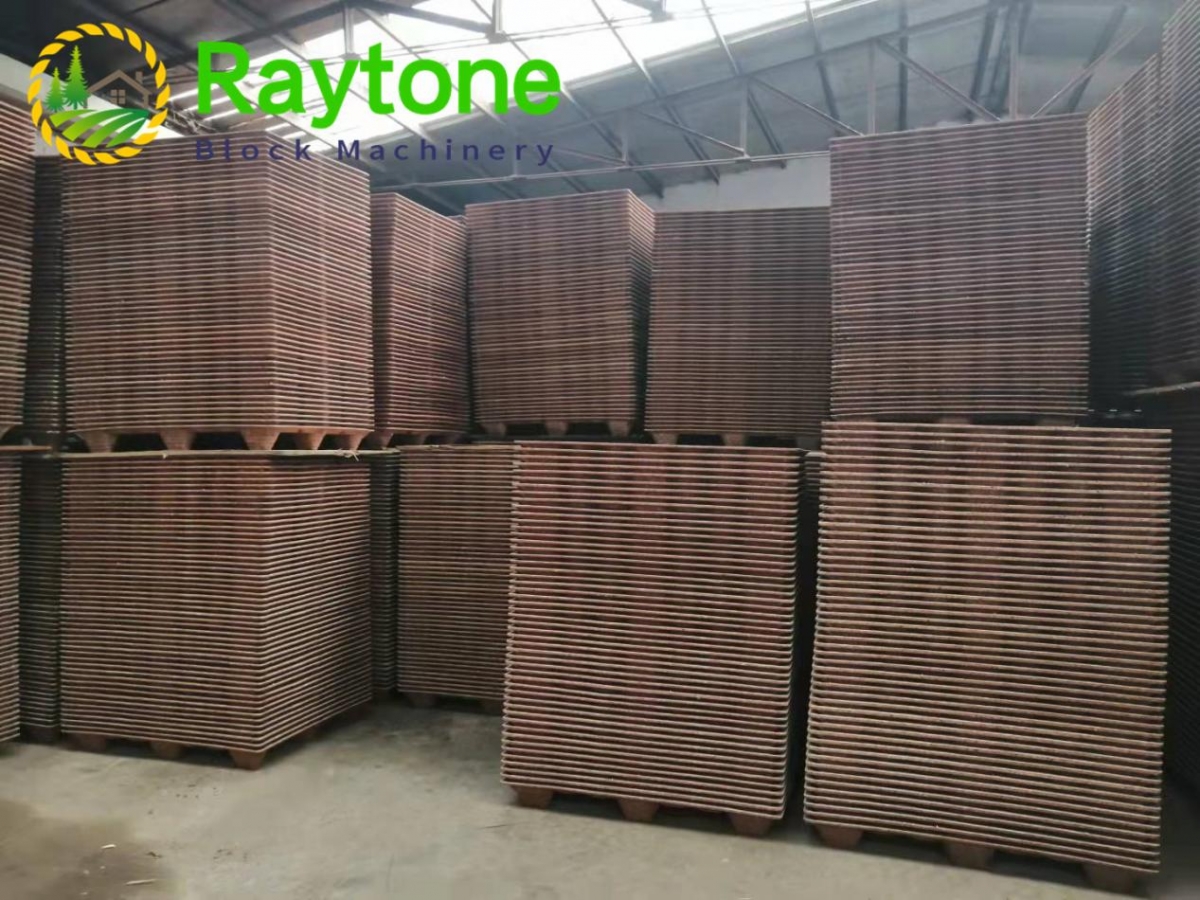

(7) Space saving: nested stacking, the height of 60 pallets is about 2.2M, which reduces the operating cost of the enterprise and saves a lot of transportation, storage and packaging costs for the enterprise; The same number of pallets saves 3/4 of space than ordinary wooden pallets. Forklifts can handle 60 pallets at a time, while ordinary wooden pallets can only carry 18-20 pallets at a time.

(8) Mataas na kapasidad na nagdadala ng pagkarga: Depende sa istraktura ng disenyo ng papag, ang kapasidad ng pagkarga ay maaaring umabot ng higit sa 3 tonelada

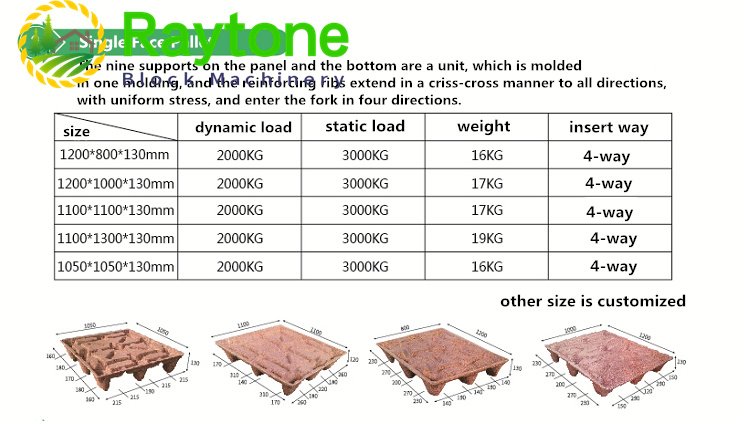

The nine supports on the panel and the bottom are one unit, which is molded in one molding, and the reinforcing ribs extend in a criss-cross manner to all directions, with uniform stress, and enter the fork in four directions.

(9) Mababa ang moisture content, karaniwang kinokontrol sa pagitan ng 6% at 8%, at hindi sumisipsip ng moisture o deform ang tray habang ginagamit.

(10) The weight is 50% lighter than the pallet products made of hard hardwood wood..

(11) Maaari itong dalhin upang matugunan ang negosyo sa pag-import at pag-export nang walang paggamot sa pagpapausok.

(12) Maaari itong gawin gamit ang mga nalalabi sa pagproseso ng kahoy at mga basurang materyales at mababang uri ng kahoy.

(13) The product is environmentally friendly and can be recycled, recycled, and reused, with low pollution and a recovery rate of up to 100%.

(14) Ang presyo ay mas mura kaysa sa tradisyonal na coniferous o broad-leaved timber.

3. Paano mapanatili ang naka-compress na papag habang ginagamit, upang mapalawig ang papag na mas mahabang buhay;

① Ang tray ay dapat na iwasang malantad sa sikat ng araw upang maiwasan ang pagtanda at paikliin ang buhay ng serbisyo.

② It is strictly prohibited to throw the goods into the pallet from a height. Reasonably determine how goods are stacked in pallets. The goods should be placed evenly. Do not stack them eccentrically. Pallets carrying heavy objects should be placed on a flat ground or object surface.

③ Mahigpit na ipinagbabawal na ihulog ang papag mula sa mataas na lugar upang maiwasang masira o mabitak ang papag dahil sa marahas na epekto.

④ When the forklift or manual hydraulic truck is working, the fork stab should be as far as possible to the outside of the pallet fork hole. The fork stab should be fully extended into the pallet, and the angle can be changed after the pallet is lifted steadily. The fork can not hit the side of the pallet to prevent the pallet from breaking or cracking.

⑤ When the pallet is placed on the shelf, a shelf-type pallet is required. The load capacity depends on the shelf structure, and overloading is strictly prohibited. Fixing methods for pallet-carrying goods The main fixing methods for pallet-carrying goods include strapping, glue binding, and stretch packaging, and they can be used together. After the protection of the cargo carried by the pallet and the cargo carried by the reinforced pallet are fixed, and the transport requirements are still not met, the protective reinforcement accessory should be selected as required. The reinforced protective accessories are made of wood, plastic, metal and other materials.

4. What size compressed pallet we have now?

Sa kasalukuyan ay nagkakaroon tayo ng laki ng

| ① | 1200 * 800 * 130mm; |

| ② | 1200 * 1000 * 130mm; |

| ③ | 1100 * 1100 * 130mm; |

| ④ | 1300 * 1100 * 130mm; |

| ⑤ | 1050 * 1050 * 130mm; |

5. ano ang proseso ng ginawang compressed wood pallet?

① Preparation of raw materials and shavings: gamit ang magaan na kahoy (ang densidad ng malalaking palyete ay tumataas ang timbang), ang hugis ng mga pinagkataman ay karaniwang 50mm ang haba, 10-20mm ang lapad, at mga 0.5mm ang kapal. Ang maliit na diyametro na kahoy, twig wood o wood processing residues ay dapat linisin ng alikabok, at ang bark content ay dapat mahigpit na kontrolin, hindi hihigit sa 5% para matiyak ang magandang shavings. Ang kapal ng shavings ay 0.3 ~ 0.5mm bilang pinakamataas na grado. Matapos ang mga wood chips ay magnetically separated, ang mga ito ay ipinadala sa isang double drum flake machine para sa pagproseso sa shavings, at pagkatapos ay ipinadala sa isang dryer. Ang moisture content ng shavings pagkatapos ng pagpapatayo ay dapat kontrolin sa hanay na 2 hanggang 3%. Ang maliliit na shavings at hindi kwalipikadong oversized shavings ay kailangang ayusin at alisin.

② Paghahalo ng pandikit: Upang maiwasang masira ang mga shavings, hindi angkop na gumamit ng high-speed glue mixing machine. Sa pangkalahatan, ginagamit ang isang roller glue mixing machine. Dalawang sistema ng pag-spray ang maaaring ibigay upang maglapat ng dalawang uri ng pandikit na hindi angkop para sa paghahalo. Sa pangkalahatan, ang isocyanate at urea-formaldehyde dagta ay halo-halong, o phenolic dagta at melamine dagta, ang sizing halaga ay 2% -15%, sa pangkalahatan ay 4% -10%. Ang metered shavings at ang quantitative urea-formaldehyde resin ay sabay na ipinapadala sa rubber mixing machine. Ang nilalaman ng tubig ng mga shaved shavings pagkatapos ng paghahalo ay dapat kontrolin sa loob ng hanay na 8-10%.

③ Paving and hot pressing: using special equipment, the paving is carried out in two steps, first paving the pallet feet and pre-pressing, and then paving the flat part of the pallet. Some shallow foot trays can also be paved at once. The punch is fixed on the upper movable beam of the hot press, and the concave die travels between the hot press and the paver. It is placed on the lower working table of the hot press and has a special demoulding device. Spread the glue-mixed wood shavings in the mold, and then pre-press and hot-press until the resin is completely cured, and then the mold can be lifted. Firstly, the shavings after sizing are quantitatively laid into a metal mold and cold-pressed for pre-forming. And then placed in a hot press to shape.

④ The whole edge: higit sa lahat para sa pag-trim, iyon ay, pag-alis ng sobrang flash sa gilid ng produkto.

6. Pag-iingat:

① Sa panahon ng paggamit ng mga pallet ng mga hydraulic truck at forklift, ang distansya sa pagitan ng mga tines ay dapat na mas malawak hangga’t maaari sa panlabas na gilid ng fork inlet ng papag, at ang lalim ng fork ay dapat na mas malaki kaysa sa 2/3 ng lalim ng buong papag.

② Sa panahon ng paggalaw ng papag, ang mga hydraulic truck at forklift ay dapat na patuloy na gumagalaw nang pataas at pababa upang maiwasan ang pinsala sa papag at pagbagsak ng kargamento na dulot ng mabilis na pagpreno at mabilis na pag-ikot.

③ Kapag ang papag ay nasa istante, ang papag ay dapat na nakalagay sa shelf beam nang matatag, at ang haba ng papag ay dapat na mas malaki kaysa sa panlabas na diameter ng shelf beam ng 50mm

Welcome to contact RAYTONE to get the price of compressed wood pallet